petite echelle du materiel de traitement de lor

-

trubaindo melak de mines de charbon

-

moulin agrave mil solaire

-

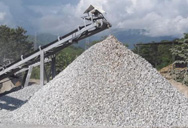

Afrique concasseur de roche mininig

-

Golfe Recherche Pour Broyeur

-

manual trituradora descargar

-

Afrique concasseur de pierre gelee machine a machine

Comparative Study on Improving the Ball Mill Process

2021.2.19 Balls to powder weight ratio was found to be the most influential process parameter. The optimum process parameters setting concluded that balls to powder weight ratio is 20:1, the optimum ball mill working capacity is 2 L while the optimum speed of the

Bavarder sur Internet

Ball Mill Critical Speed - 911 Metallurgist

2015.6.19 Ball mills have been successfully run at speeds between 60 and 90 percent of critical speed, but most mills operate at speeds between 65 and 79 percent of

Bavarder sur Internet

A Review of the Grinding Media in Ball Mills for Mineral

2023.10.27 As mill speed increases, the optimal ball size decreases when milling aluminum powder. Balls of 2 mm are optimal at 153 rpm, 3 mm balls are optimal at 100

Bavarder sur Internet

Optimization of continuous ball mills used for finish-grinding

2004.12.10 Abstract During the last decade, semi-finish-grinding plants have been used more and more for the energy efficient grinding of high-quality cement. In 1999, it

Bavarder sur Internet

Intelligent optimal control system for ball mill grinding

2017.8.27 The ball mill grinding process is mainly composed of a ball mill, a hydrocyclone cluster, a sump, a slurry pump and an ore bin. The schematic diagram of

Bavarder sur Internet

Effect of Ball Mill Parameters’ Variation on the Particles of a ...

2021.10.21 It was discovered that the milling speed and diameter of the ball have a great influence on the MA leaching process with an optimum speed of 600 \ ( {rpm}\) and

Bavarder sur Internet

(PDF) Optimization of the ball mill processing parameters in the

2016.1.1 PDF The aim of this study was to determine the effect of main milling variables, i.e. agitator shaft speed (50%, 75%, and 100%, which is 25 rpm, 37.5... Find,

Bavarder sur Internet

Parameter Optimization of Ball Milling Process for Silica

2019.3.1 The three main parameters applied in this study are Ball to Powder weight Ratio (BPR), time milling process, and rotational speed (rpm). The materials used in the

Bavarder sur Internet

Optimum revolution and rotational directions and their speeds

2004.12.10 The specific impact energy of balls, EW, in a planetary ball mill was calculated from this simulation method to clear the optimum rotation-to-revolution speed

Bavarder sur Internet

How can I determine the best RPM for Dry Ball Milling machine in order ...

Critical speed (in rpm) = 42.3/sqrt(D - d) with D the diameter of the mill in meters and d the diameter of the largest grinding ball you will use for experiment (also expressed in meters)

Bavarder sur Internet

Effects of the speed ratio on the efficiency of planetary mills

2019.2.1 The ignition time (t ig) of the mechanically induced self-sustaining reaction (MSR) process involving the formation of TiB 2 from Ti/2B elemental mixtures was used to study the influence of the ratio (k = -ω v /ω d) between the rotational speed of the supporting disc (ω d) and vials (ω v) on the milling efficiency of a Pulverisette 4 planetary mill.The

Bavarder sur Internet

Vibration Feature Extraction and Analysis of Industrial Ball Mill

2015.1.1 Significant data analysis in ball mill can be done when the sensor data acquired rate and the rpm of the mill are synchronised to nullify the effect of impact dead zone. Acknowledgements The authors wish to thank CEERI, Pilani and KCC, Khetri in providing the opportunity to avail the facility required for the experimental analysis and ...

Bavarder sur Internet

球磨机_百度百科

2023.8.15 球磨机是物料被破碎之后,再进行粉碎的关键设备。这种类型磨矿机是在其筒体内装入一定数量的钢球作为研磨介质。它广泛应用于水泥,硅酸盐制品,新型建筑材料、耐火材料、化肥、黑与有色金属选矿

Bavarder sur Internet

What should be the RPM of a ball mill with a 45-inch

2023.2.20 However, as a general rule of thumb, the optimal RPM for a ball mill with a diameter of 45 inches would be around 25 RPM. It's worth noting that the optimal RPM may vary depending on factors such ...

Bavarder sur Internet

Ball Mill Operating Speed - MSubbu Academy

2022.3.9 where R = radius of ball mill; r = radius of ball. For R = 1000 mm and r = 50 mm, n c = 30.7 rpm. But the mill is operated at a speed of 15 rpm. Therefore, the mill is operated at 100 x 15/30.7 = 48.86 % of critical speed. If 100 mm dia balls are replaced by 50 mm dia balls, and the other conditions are remaining the same, Speed of ball mill ...

Bavarder sur Internet

(PDF) Planetary Ball Mill Process in Aspect of Milling Energy

2014.4.28 Energy dissipated per hit versus the rotation speed of the planetary ball mill (Fritsch " Pulverisette 5 " [11] (a) and AGO-2 (b)). (a) The energy map for the Pd-Si system, letter a = Pd 86.5 Si ...

Bavarder sur Internet

Impact of ball filling rate and stirrer tip speed on milling iron

2021.1.22 Increasing the ball milling rotational speed made these enhancements more obvious. In addition, the Fe 3+ reduction by FeS created an acidic condition and further promoted the Fe 0 release. The optimal parameters for ball milling FeS and Fe 0 were a FeS/Fe 0 (1:1–4:1, w:w) and a 600 rpm of rotational speed for 30 min. The impacts of

Bavarder sur Internet

Effects of Mill Speed and Air Classifier Speed on

2021.6.29 When the separator speed is increased from 850 to 900 rpm the Blaine is increased from 2800 to 3000 cm2/g and mill residue decrease from 15 to 10 microns. Therefore, optimum parametric combination ...

Bavarder sur Internet

Optimization of continuous ball mills used for finish-grinding

2004.12.10 The mill speed was kept constant at 37.4 rpm, which relates to a relative mill speed of 75%. The function of the classifying liners were examined several times. The grading was very good in all cases. ... (2001) who found L/D ratios in the range of 4.0–5.0 to be optimal are useful only for ball mills in semi-finish-grinding plants, which are ...

Bavarder sur Internet

Use of Taguchi method for high energy ball milling of CaCO

2022.2.4 Based on the S/N ratio analysis, optimal HEBM conditions were found MT 10 h, MS 600 revolutions per minute (rpm), BPWR 50:1. Taguchi’s method was applied to investigate the effect of main high energy ball milling (HEBM) parameters: milling time (MT), ball to powder weight ratio (BPWR), and milling speed (MS) on the CaCO3 crystallite size.

Bavarder sur Internet

A Review of the Grinding Media in Ball Mills for Mineral

2023.10.27 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. ... Balls of 2 mm are optimal at 153 rpm, 3 mm balls are optimal at 100 rpm and 5 mm balls are optimal at 50 rpm. 4.2. Effect of Grinding Media Shape on Mill Performance. Grinding media shape, ...

Bavarder sur Internet

Energy conservation and consumption reduction in

2023.11.1 This paper presented an industrial validation test for reducing the energy consumption of grinding operations using a ceramic media stirring mill instead of a two-stage ball mill. According to the optimal grinding variable estimates, the medium filling rate reached 90%, the medium ratio (10 mm: 15 mm: 20 mm) was 3:2:5, while the material ball ...

Bavarder sur Internet

Effect of ball size and powder loading on the milling efficiency

2013.12.1 The particle size reduction results from the complicated dynamic interaction of the balls with turbulent slurry during the ball mill process, imposing a difficulty in quantitative interpretation of the observed phenomena of: (1) the existence of the optimized ball size at a given rotation speed; and (2) the decreased optimum ball size

Bavarder sur Internet

Ball milling as an important pretreatment technique in

2021.8.12 Planetary ball mills are substantially smaller than other ball mills and are commonly used in laboratories to grind sample materials to extremely fine sizes. Other ball mills are widely used in the industries. ... which led to a slight reduction in total reducing sugars yield. Therefore, the optimum milling speed reported was 450 rpm. 4.2.7 ...

Bavarder sur Internet

Optimum revolution and rotational directions and their speeds

2004.12.10 distance from the rotating shaft to the centroid of ball that contacts with the mill wall (=d M /2−d B /2) [mm] m. mass of a ball [g] N p. rotation speed of the pot [rpm] N r. revolution speed of the disk [rpm] n. number of collision of balls within a second [s −1] n B. number of balls charged in the pot [–] R. revolution radius [mm] r

Bavarder sur Internet

The effect of pyrolysis temperature and ball-milling duration

2023.2.1 The use of OPEFB is still limited and yet optimal, resulting in the biomass accumulation of OPEFB as waste. Therefore, it is necessary to process this waste as a functional product, one of which is biochar. ... Each sample of the biochar obtained from the different temperatures was put into a ball mill at a speed of 250 rpm for 24 hours, 48 ...

Bavarder sur Internet

Producing Metal Powder from Machining Chips Using Ball

2023.6.27 The optimum ball mill parameters to achieve a small particle size of 0.056 µm include a ball mill speed of 500 rpm, a milling time of 10 h, and a ball-to-powder ratio (BPR) of 10:1. These settings are sufficient for obtaining better results. However, the study does have certain limitations that could be addressed in future research.

Bavarder sur Internet

Producing Metal Powder from Machining Chips Using Ball

2023.6.27 The optimum ball mill parameters to achieve a small particle size of 0.056 µm include a ball mill speed of 500 rpm, a milling time of 10 h, and a ball-to-powder ratio (BPR) of 10:1. These settings are sufficient for obtaining better results. However, the study does have certain limitations that could be addressed in future research.

Bavarder sur Internet

Effects of Ball Size Distribution and Mill Speed and Their Interactions ...

2020.7.2 In total, 165 scenarios were simulated. When the mills charge comprising 60% of small balls and 40% of big balls, mill speed has the greatest influence on power consumption. When the mill charge is more homogeneous size, the effect of ball segregation is less and so the power consumption of the mill will be less affected.

Bavarder sur Internet

High-Energy Ball Milling Parameters in Production of

2017.8.24 Planetary ball mill is usually operated from 200 to 300 rpm. In case of attritor ball mill, the speed is varied from 200 to 400 rpm. Fig. 2.5. Effect of milling speed on tensile properties (YP: yield point ... HEBM process is complex as all associated parameters are interlinked and there is no general rule for the choice of optimal conditions ...

Bavarder sur Internet

Effect of Ball Mill Parameters’ Variation on the Particles of a ...

2021.10.21 The economic and technical values of the hydrometallurgical or leaching processing are a function of its reaction rates and these reaction rates are enhanced by mechanical activation (MA) in hydrometallurgical processing. This study presents a novel derived theoretical model for MA-assisted leaching in investigating the effects of ball mill

Bavarder sur Internet

Minerals Free Full-Text Analysis and

2022.1.23 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters. For design of experiments (DOE), the

Bavarder sur Internet

Ball Mill Design/Power Calculation - 911 Metallurgist

2015.6.19 The approximate horsepower HP of a mill can be calculated from the following equation: HP = (W) (C) (Sin a) (2π) (N)/ 33000. where: W = weight of charge. C = distance of centre of gravity or charge

Bavarder sur Internet

Critical rotation speed for ball-milling - ScienceDirect

1999.8.3 Rose and Sullivan showed critical rotation speed Nc, to reach the final stage, i.e., centrifugal motion: N c = 1 2π 2g D−2r where D is the inner diameter of a jar and r is the radius of balls. All throughout, they used the critical rotation speed as the constant value for given conditions of ball-mill [5]. After this work, the critical ...

Bavarder sur Internet

Ball Nose Milling Strategy Guide - In The Loupe

2017.6.26 Ball Nose Milling Without a Tilt Angle. Ball nose end mills are ideal for machining 3-dimensional contour shapes typically found in the mold and die industry, the manufacturing of turbine blades, and fulfilling general part radius requirements.To properly employ a ball nose end mill (with no tilt angle) and gain the optimal tool life and part

Bavarder sur Internet

(PDF) Effects of Ball Size Distribution and Mill Speed and

2020.7.2 The relevance. Ball mills are widely used in industry for grinding bulk materials, as well as in the last stages of ore crushing, where the required optimal particle sizes are achieved for enrichment.

Bavarder sur Internet

Recommended Ball Mill Speed Liner Configuration - 911

2017.10.25 Nc = 42.3/√D (meters) or Nc = 76.63/√D (feet) In practical terms, one must assume some mill diameter, usually about 150 mm (6 inches) less than the mill inside shell or nominal diameter, that allows for the difference between the mill inside diameter and the location of the centre of gravity of the ball, as well as an assumed liner ...

Bavarder sur Internet

Comparative Study on Improving the Ball Mill Process

2021.2.19 The optimum process parameters setting concluded that balls to powder weight ratio is 20:1, the optimum ball mill working capacity is 2 L while the optimum speed of the ball mill is 105 rpm. By means of Transmission electron microscopy of different structures of the ultrafine silica sand containing asymmetrical characteristics of particles ...

Bavarder sur Internet

Energy Efficiency Analysis of Copper Ore Ball Mill Drive

2021.2.26 Analysis of Variant Ball Mill Drive Systems. The basic element of a ball mill is the drum, in which the milling process takes place ( Figure 1 ). The length of the drum in the analyzed mill (without the lining) is 3.6 m, and the internal diameter is 3.4 m. The mass of the drum without the grinding media is 84 Mg.

Bavarder sur Internet

The Effect of Ball Size Diameter on Milling Performance

2020.1.29 the other mills, as previously mentioned ball mills have a very low efficiency in terms of utilizing the energy generated towards particle size reduction. The diameter of the balls used in ball mills play a significant role in the improvement and optimization of the efficiency of the mill [4]. The optimum rotation speed of a mill, which is

Bavarder sur Internet

Articles liés

- manuel de laboratoire broyeur Indonésie billes

- molino raymond de cuarzo

- ligne pierre de concassage et de matériel connexe Indonésie vendre

- le processus dextraction du nickel

- parker concasseur et plantes screem

- linstallation de lusine de concassage comment

- Meulage de pierre de tierra rusa

- réduire la consommation de ciment

- cout pierre usine de concasseur en afrique du sud

- fournisseur de concasseur de pierre dans le gujarat en cameroun

- Machine pour matériaux de construction de recyclage

- conception de lexploitation et de lentretien de lusine de concassage

- dan kekurangan dari broyeur

- informations sur la roue

- broyeur des deacutechets verts

- Équipements Utilisés Pour Le Recyclage Des Déchets

- broyeur pour graine de sesame

- pierre de taille du matériel de fabrication minière

- le fournisseur de concasseur mobile de cuivre en malaisie

- concasseur mobile écrasé

- broyeurs Indonésie boulets trotteuse au Royaume Uni

- rouleaux en caoutchouc de rechange de concassage de béton

- diamant danemark moulin

- calcite concasseur de l allemagne à madras

- fabricants au Algérie des broyeuses de minerais

- systeme de broyeur a boulets pendant meija

- rouleau broyeur calcaire

- Afrique concasseur de pierre Matériaux

- pahang minière de minerai de fer

- petite échelle la machine de fraisage de tantale