fabrication de ciment dossiers

-

ouverture dune mine de charbon dans vierfontein

-

les coûts d exploitation de concasseur mobile

-

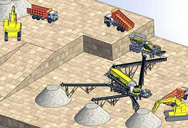

concasseur usine lpierre

-

Price List Of Jc Jaw Broyeur In India

-

récipient de broyage de plantes pour la fabrication des ciments européen

-

broyeur dolomite mobile Indonésie louer indonessia

(PDF) Drives for large vertical roller mills

2017.1.1 A new market study by OneStone Consulting is based on reference lists of the leading vendors in vertical mill sector, including

Bavarder sur Internet

Proven vertical mill solutions References - Gebr. Pfeiffer

134 行 Cement: Costa Rica: Elementia, Caldera: MVR 2500 C-4: Cement: Kenya:

Bavarder sur Internet

What’s Up with Vertical Mill Drives? - IEEE Conference

2019.5.2 What’s Up with Vertical Mill Drives? Abstract: Drive systems for large vertical mills have proven to be a reliability issue for many cement producers. As mill

Bavarder sur Internet

Drive systems for vertical roller mills - IEEE Xplore

2017.5.25 Because of simple scalability and low energy consumption, the vertical roller mill is a key part for single mill cement lines. The limits of material throughput of

Bavarder sur Internet

CEM Drive More sustainable power for vertical mills

2021.7.12 sustainable drive system for large vertical roller mills, the CEM Drive. The smart design of this versatile mill drive system incorporates IoT technology to deliver the

Bavarder sur Internet

Article in Cement International 5-2017 - FLSmidth

2018.12.6 Today, vertical roller mills (VRMs) with highest installed drive power are used in the cement and slag grinding processes and up to now, they did not reach their

Bavarder sur Internet

Review on vertical roller mill in cement industry its

2021.1.1 For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials. With the grinding capacity of a vertical roller

Bavarder sur Internet

Introducing the Vertical Roller Mill with Driven Rollers: An

2015.8.31 Abstract: With the market demand for efficient, highly flexible, and high-capacity plants for cement production, it was time to develop an innovative drive concept

Bavarder sur Internet

The future of vertical roller mill drive systems - ResearchGate

2017.1.1 Abstract. Today, vertical roller mills (VRMs) with highest installed drive power are used in the cement and slag grinding processes and up to now, they did not

Bavarder sur Internet

Drive systems for vertical roller mills - Semantic

This paper will explore the evolution of vertical mill drive system designs and focus on some of the strategies used by cement producers to offset potential losses from large vertical millDrive system failures.

Bavarder sur Internet

Ball mill - CEMTEC - double - DirectIndustry

Double chamber ball mills for the cement industry come in various designs: For bearings, either slide or slide shoe bearings can be chosen. Possible drives include gear rim/pinion, lateral, or central drives. If the processing

Bavarder sur Internet

Cement Mill Drives PDF Electric Motor Cement - Scribd

2020.5.13 In modern cement mills, a microprocessor-based control scheme is used. 2. Mill Drives: Requirements of mill drives are: High starting torque. The starting current must be limited to a maximum of two times the full load value to minimize voltage dips. An overload capacity of 50% for 1 min occurring for 4 times an hour.

Bavarder sur Internet

(PDF) ANALISIS PENGGILINGAN DAN PENCAMPURAN ...

2022.1.11 Fernando. E, J., (2020). Spesifikasi Alat dan Prinsip Kerja Vertikal Roller Mill di Pabrik Baturaja II. Departement Cement Production Cement Mill 56 : PT. Semen Baturaja (Persero).Tbk.

Bavarder sur Internet

Roller Press - KHD Humboldt Wedag

Simply put, the roller press is the most energy-efficient grinding machine on the market. Since its commercial introduction into the cement industry by KHD in the 1980s, hundreds of them have been installed in the cement and minerals industries, in both finish and semi-finish applications. And with the lowest specific energy consumption among comparable

Bavarder sur Internet

Loesche Mills for Cement and Granulated Blast Furnace

2017.8.11 Grinding of cement clinker and granulated blast furnace slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche. The first use of a Loesche mill, with a grinding track diameter of only 1.1 metres, was used as long ago as 1935. However, the breakthrough in grinding this type of material on the vertical

Bavarder sur Internet

ANALISIS PENGGILINGAN DAN PENCAMPURAN ...

2024.1.3 Vol.1 No.1 Januari 2022 Vertical Roller Mill memiliki banyak bentuk yang berbeda, tetapi bekerja pada prinsip sama. Semua jenis Vertical Roller Mill memiliki bentuk yang sama yaitu dengan adanya ...

Bavarder sur Internet

Chapter Six: Some Operating Guidelines - Vertical Roller Mill

2022.4.6 An interesting historical fact is that a vertical roller mill uses the same operating principle as the pistrium or pistrinum, an antique Roman grain mill. The largest grain mills used worked a ...

Bavarder sur Internet

quadropol® - thyssenkrupp Polysius

Mombasa Cement Ltd. ordered a QMK² 24/12 with three roller units for the 5,000 tons per day kiln line. In addition, the raw material grinding process will be supported by a QMR² 48/24. For the 4,000 tons per day kiln line Shiva Cement Ltd. contracted a quadropol® vertical roller mill for grinding pet coke with a QMK² 32/16.

Bavarder sur Internet

Modeling operational cement rotary kiln variables with

2022.10.20 1. Introduction. Although the cement industry globally is one of the most important parts of the economic sector, cement production is an extremely CO 2 emission process. Several investigations have been conducted to reduce cement production issues (Chipakwe et al. Citation 2020).They were focused mainly on cement chemistry, and few

Bavarder sur Internet

Modeling of energy consumption factors for an industrial cement ...

2022.5.9 Cement production is one of the most energy-intensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year's global electrical energy production. It is ...

Bavarder sur Internet

Cement mills and raw mills for high throughput

High throughput rates, permanent plant availability , optimized maintenance concepts – features of the MVR mill and the patented MultiDrive ® enabling Gebr. Pfeiffer to meet the ever rising expectations of the industry.

Bavarder sur Internet

INVT GD5000 MV Drive for Cement Raw Mill 11KV 4MW

2020.4.4 5) Formation of cement clinker. 6) Cement grinding. Cement grinding is the last and power-consuming step in cement process, which will grind cement clinker to proper grain size. 7) Cement packaging. The cement is delivered in two ways of bag and bulk. 3.Project information and system solution. 1) Vertical raw mill information

Bavarder sur Internet

MAAG® GEAR CEM Drive - FLSmidth

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement plant’s lifetime.

Bavarder sur Internet

CEM Drive More sustainable power for vertical mills

2021.7.12 for vertical mills. WE DISCOVER POTENTIAL. MAAG® CEM Drive concept MAAG® CEM Drive Gear nit 3 ... entire cement manufacturing process depends on it. So, above all . things, it needs to be reliable. ... information and data contained in this brochure are for general reference only and may change at any time. C 06-21 500-8

Bavarder sur Internet

Ring-geared mill drives - Grinding ABB

Mill application features. Frozen charge protection – Detects frozen charge in the mill, minimizing equipment wear and liner replacements.; Coupling supervision – Detects if a failure or slippage occurs in the couplings and stops the system in case, preventing major damages.; Stand-still detection – Prevents the motors from re-starting if the mill is still

Bavarder sur Internet

PROCESS CONTROL FOR CEMENT GRINDING IN

2017.10.27 The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 30-40% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and

Bavarder sur Internet

OK™ cement mill The most energy- efficient mill for

2019.4.10 finish grinding of Portland cement, slag and blended cements. The mill consistently uses five to ten percent less power than other cement vertical roller mills, and in comparison with traditional ball mill operations, the energy requirements for the OK cement mill is 30-45 percent lower for cement grinding and 40-50 percent lower for slag.

Bavarder sur Internet

SikaGrind® for vertical roller mills

2024.1.21 The intergrinding of Portland-Limestone Cement (PLC) with Vertical Roller Mills avoids excessive limestone surface. Particle Size Distribution of 2 cements with identical limestone content, ground in diferent mill types. The VRM grinds the clinker to a higher degree, but the fineness of the lime-stone is not increased proportionally.

Bavarder sur Internet

Stirred mills - Metso

2022.7.12 The vertical arrangement, on the other hand, allows the drive train to be entirely supported by the mill body which leads to a small footprint and simple foundation. Furthermore, the vertical arrangement does not require any slurry seals or inlet feed pressure. Lower operating cost SMD’s power intensity is optimized to achieve efficient

Bavarder sur Internet

A Survey and Analysis on Electricity Consumption of Raw Material Mill ...

2021.1.22 In the whole process of cement production, the electricity consumption of a raw material mill accounts for about 24% of the total. Based on the statistics of the electricity consumption of the raw material mill system of 1005 production lines in China between 2014 and 2019, it is found that the average electricity consumption of the raw material

Bavarder sur Internet

Cement - Sumitomo Drive

2 天之前 Cement Manufacturing. Your power transmission drives must be durable, reliable and efficient. This isn’t an option; this must be the standard. Recognizing this challenge, we offer solutions designed to withstand the harshest conditions while delivering the highest level of performance. Our drives, distinguished for their robust design, easy ...

Bavarder sur Internet

MAAG® IronDrive Gear Unit - FLSmidth

With a new bearing design, the MAAG IronDrive is our most efficient drive for vertical roller mills from 1000 kW to 9000 kW. And, like the original MAAG® Gear Unit, it benefits from a special planetary gear arrangement that ideally divides the gear ratio between the bevel and planetary gear stages – providing the highest torque transmission ...

Bavarder sur Internet

Digitization and the future of the cement plant

2020.9.16 Our reference plant is a five-stage preheater-calciner kiln with a vertical raw mill and two cement ball mills. It has an annual production capacity of one million metric tons of cement and produces several types

Bavarder sur Internet

IG PERFORMANCE PARTS Mill Liners for Ball Mills

2021.1.22 suit all mill OEM's. Key benefits. Cement grinding. The feed for a cement grinding unit will normally be dry and. needs to be ground to a high degree of fineness. To achieve this efficiently, most mills will be split into two chambers. The first is set up for coarse grinding with a target to grind the feed materials down to around 1 mm.

Bavarder sur Internet

ANALISA KINERJA ALAT VERTICAL CEMENT MILL DI ...

2023.11.8 Vertical Cement Mill digunakan untuk mencampurkan dan menghaluskan clinker dan bahan – bahan korektif. Selain itu, alat ini juga digunakan sebagai pengering dengan memanfaatkan udara panas dari

Bavarder sur Internet

(PDF) Performance Evaluation of Vertical Roller Mill in Cement

2017.9.11 Keywords: Vertical roller mill, cement grinding, performance evaluation . INTRODUCTION. Cement production is highly energy consuming process . with energy utilization of around 110-150 kWh/t (Villa,

Bavarder sur Internet

(PDF) 2020 Technology and Operation of a Hot Rolling Mill

2020.1.3 Abstract and Figures. The state-of-the-art of both technology and operational practice of a hot rolling mill are discussed. The focus is first on the control of entry temperature in the finish ...

Bavarder sur Internet

The world's first vertical roller mill with driven rollers IEEE ...

2014.4.17 As the market demands efficient, highly flexible and high capacity plants for cement production, it was time to develop an innovative drive concept to cope with these demands: the world's first vertical roller mill with driven rollers. With this concept, it is the rollers of the vertical roller mill that are driven, not - as is usually the case - the grinding

Bavarder sur Internet

(PDF) The latest innovative technology for vertical roller mills ...

2014.4.1 Two mill systems are employed for most coal grinding applications in the cement industry. These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on ...

Bavarder sur Internet

MAX Drive Peak performance for your vertical mill

2020.11.19 this modular drive concept specifically for vertical mill. The matched drive units, torque split, reliable components and our proven track record makes our MAAG MAX Drive an ideal fit for cement and slag grinding. The modular concept with only one vertical motor directly connect-ed to the gear casing allows for a compact arrangement without

Bavarder sur Internet

Articles liés

- Concasseur À Marteaux Principe De Fonctionnement

- utilise minerai dor machoire prix de concasseur malaisie

- Calcul De La Puissance Du Convoyeur A Vis Au Royaume Uni

- meilleur broyeur de manioc

- sable utilise les installations de lavage a vendre irlande

- broyeur à charbon rouleau fabricant inde

- pour le broyage du clinker ciment

- la fabrication du ciment machine a carreaux

- caracteristiques calcaire de concassage pierre

- concsseur a cone bergeau omnicone sx

- concasseur à machoires entre

- foto maquina Meulage de pierre de tierra

- sayaji concasseur Indonésie mâchoires 30 24 baroda

- utilisation de grade de ceinture pour le broyage

- moulin à haute pression en Inde

- giratoire Concasseur à laver

- lavage du sable de silice

- Grès Décoration Fabrication de sable de concassage de pierre

- machine de pulvérisation à coimbatore

- planta de beneficio de china maanshan

- moulage de pâte locale au nigeria

- pratique de broyage pour le minerai de fer amendes

- équipement de fabrication de gypse Indonésie vendre

- poids brut du véhicule du concasseur de béton

- Almeida Concasseur à Jabalpur

- concassage au Pakistan Landis

- broyeurs en acier chrome haute teneur en carbone parties

- difference entre concassage et de broyage samac

- la securite du systeme de lubrification moulin

- fabricant de boulet de broyage