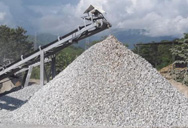

le concassage dans les carrieres

-

rappel sous forme de broyage

-

installations de criblage de carriere qui signifie

-

centrale à charbon moulin

-

moulin à marteau hydraulique

-

technique de fonctionnement de l'appareil tamiseur vibrant pdf

-

machine sans oxygène de cuivre au Rwanda

Ball feeder - Metso

Optimizing grinding mill performance. Features. Metso's Select™ ball feeder utilizes a simple and robust design for continuous and automatic grinding media consumption for optimized horizontal grinding mill performance.

Bavarder sur Internet

Ball milling as a mechanochemical technology for

2020.9.1 While using a vibratory tube mill, a cylinder containing balls and powder is vibrated at a high frequency and small amplitude to obtain high milling forces (Fig. 2 d).

Bavarder sur Internet

(PDF) Grinding in Ball Mills: Modeling and Process

2012.6.1 PDF The paper presents an overview of the current methodology and practice in modeling and control of the grinding

Bavarder sur Internet

Ball milling as an important pretreatment technique in

2021.8.12 Both attrition and planetary ball mills were effective to reduce particle size, minimize waste generation, and loss of biomass, as compared to tumbling ball mill .

Bavarder sur Internet

Ball milling: a green technology for the

Lu et al. employed the ball mill to obtain nanocrystals from bamboo pulp by a mechano-chemical treatment in the presence of phosphoric acid. 38

Bavarder sur Internet

Ball-milled biochar for alternative carbon electrode

2019.4.3 29 Citations Explore all metrics Abstract Ball-milled biochars (BM-biochars) were produced through ball milling of pristine biochars derived from different biomass at three pyrolysis temperatures (300, 450,

Bavarder sur Internet

The effect of pyrolysis temperature and ball-milling duration

2023.2.1 (Naghdi et al., Citation 2017) said that the manufacture of bio-char using a ball mill with a sonification process could reach a particle size of up to 60 nm with a

Bavarder sur Internet

(PDF) Comparative comminution efficiencies of rotary,

2021.4.1 Kinetic energy of the ball media and ball-to-biomass matter surface contact points in the three ball mills, used to determine their major mechanical stresses. RBM

Bavarder sur Internet

Comparative comminution efficiencies of rotary, stirred and

2021.7.15 Milling devices used: (a) knife mill, (b) impact mill (IM), (c) rotary ball mill (RBM), (d) stirred ball mill (SBM), and (e) vibratory ball mill (VBM). Before final

Bavarder sur Internet

Integrated approach for ball mill load forecasting

2021.2.5 In the grinding process, the vibration signal generated by ball mill contains useful information related to internal load parameters, which can be used to determine mill load parameters indirectly. 2,3

Bavarder sur Internet

AMIT 135: Lesson 7 Ball Mills Circuits – Mining

Mill Type Overview. Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns.; The Diaphram or Grate Discharge mill keeps coarse particles within the mill

Bavarder sur Internet

(PDF) Grinding in Ball Mills: Modeling and Process

2012.6.1 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation. It consists of one or more rotating cylinders partially filled with grinding balls (made ...

Bavarder sur Internet

pièces de machine à coke cavalier

\n \n Machines Distributrices Usagées Montréal \n. C'est ainsi que cette nouvelle entente à confirmé DTC distributrice comme leader au niveau des pièces et de la réparation de machines distributrices dans le grand Montréal.À travers la vente de pièces et la réparation,la revente de machines distributrices reconditionnées aigidaire ou coke ou

Bavarder sur Internet

Ball milling: a green technology for the preparation and ...

Lu et al. employed the ball mill to obtain nanocrystals from bamboo pulp by a mechano-chemical treatment in the presence of phosphoric acid. 38 The pulp was firstly pre-treated using a Fibre Dissociation Device. The obtained material was then ball milled for 1.5–3.5 hours at 400 rpm in the presence of phosphoric acid to give a transparent ...

Bavarder sur Internet

(PDF) Optimization and transformation of 300MV units steel ball

2019.11.7 Abstract and Figures. Comprehensive treatment,we should have a test on the 300 MV unit steel ball coal mill pulverizing system.At the same time,analyze the main operating parameters before ...

Bavarder sur Internet

TECHNICAL SPECIFICATION OF WET BALL MILL

2023.7.14 The Gravimetric feeder feeds limestone to Wet ball mill system. The Wet Ball Mill system consists of Wet Ball Mill, Wet Ball Mill Lubrication system, Mill circuit tank with an agitator, Mill circuit Pump, Mill Hydro cyclone, 3-way distributor and accessories. The Wet Ball Mill is the wet horizontal type. The Process water is supplied to Wet ...

Bavarder sur Internet

Ball Mill - RETSCH - powerful grinding and homogenization

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications. Cooling, heating cryogenic grinding.

Bavarder sur Internet

干细胞培养中使用的feeder如何发挥重要功能?南开刘林团队 ...

2019.1.1 近,南开大学 刘林 教授课题组在 Nature Communications 上在线发表了题为 Feeders facilitate telomere maintenance and chromosomal stability of embryonic stem cells 的研究论文,结果表明饲养层细胞对于ESCs维持端粒长期稳定,自我更新和发育多能性具有重要作用。. 研究发现, 相对于 ...

Bavarder sur Internet

feeder charbon et ball mill - lesconditionsdelacroissance

mills with the rod mill and ball mill laboratory work indices. Note, in Figure. 1, that the rod mill product slope is less than 0.5 due to an extra amount of nes present being fi fi ner than 650 μm. These fi nes proceed to the ball mill improving the ball mill effi ciency. Also, the plotted rod mill P80 value, as shown in Figure 1, is 2900

Bavarder sur Internet

How it Works: Crushers, Grinding Mills and Pulverizers

2017.6.2 The feed enters one end of the ball mill, and discharges out the other end. Ball mills vary greatly in size, from large industrial ball mills measuring more than 25 ft. in diameter to small mills used for sample preparation in laboratories. Rod mills are similar to ball mills and use metal rods as the grinding media. Pebble mills use rock ...

Bavarder sur Internet

What’s the Difference Between SAG Mill and Ball Mill

2019.11.26 The biggest characteristic of the sag mill is that the crushing ratio is large. The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the

Bavarder sur Internet

charbon Ball Mill usine

Chine Broyeur à boulets de ciment et du charbon moulin à billes Trouver les prix et les détails complets sur Ball Mill,broyeur à boulets de charbon,Machine minière Ciment Mill produits du Fournisseur ou du Fabricant Luoyang Zhongtai Industries Co., Ltd.. ... feeder charbon et de lusine de charbon loziska-skf. usine de charbon grind ...

Bavarder sur Internet

贴片机供料器(feeder)飞达的种类,如何工作 - 知乎

2020.10.21 贴片机供料器(feeder)飞达的种类,如何工作. 贴片机 也称作贴装机,是SMT行业非常重要的核心机器,SMT整线的生产效率和产能由贴片机决定,行业中也有高速、中低速(多功能)机之分,贴片机通过贴装悬臂控制的贴装头(贴装头上装有吸嘴)吸嘴来

Bavarder sur Internet

charbon Feeder Et Ball Mill - galeria-zdjec2

Drum feeders are another type of ball mill feeder. These feeders are generally used to add wet or dry materials to the ball mill. The drum feeder consists of a drum-shaped container that is rotated by a motor. The material is added to the drum and moves along with it until it reaches the end and falls into the ball mill. Vibratory Feeders ...

Bavarder sur Internet

mills charbon charbon feeders - avocats-droit-du-travail

Introduction à la technologie de traitement système de la ligne de production du concasseur à mâchoires . Les concasseurs à mâchoires ne fonctionnent généralement pas de manière indépendante, mais avec les concasseurs à cône, l'impact concasseurs, machines à fabriquer du sable, cribles vibrants, etc., constituent un ensemble complet de sable et

Bavarder sur Internet

Ball Mill Ball Mills Wet Dry Grinding DOVE

3 天之前 DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h-1000 g/h). For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity range of (0.3 TPH – 80 TPH). With over 50 years experience in Grinding Mill Machine fabrication, DOVE Ball Mills as ...

Bavarder sur Internet

Effect of ball and feed particle size distribution on the milling ...

2018.6.1 The same policy is employed for the make-up charge where adding different ball sizes is done in order to optimize the mill performance. Chimwani et al. (2015) developed a simulation program that could predict optimal make-up balls to be added in order to achieve a required product fineness.

Bavarder sur Internet

Flexible milling and grinding solutions that last FLSmidth

Optimal feed material milling and grinding solutions. Carefully crafted to meet your milling and grinding needs, our robust and well-designed solutions are highly adaptable for a range of feed materials. With compact layouts, long-lasting wear parts and easy access for maintenance, you can save on civil, operation and maintenance costs.

Bavarder sur Internet

一种新型自动加球机的研制-Development of a new type of ...

2015.11.13 Abstract: Intended to introduce the structure, operating principle and design method of the new type of automatic ball adding machine. The design to catch the ball from the storage box by installing a device in the surface of rotary drum, using laser sensor to make non-contact inspection of the steel ball, and equipped with PLC control

Bavarder sur Internet

Ball Mill Maintenance Installation Procedure - 911

2016.10.19 Ball Mill Sole Plate. This crown should be between .002″ and . 003″, per foot of length of sole plate. For example, if the sole plate is about 8′ long, the crown should be between .016″ and .024″. Ball Mill Sole Plate. After all shimming is completed, the sole plate and bases should be grouted in position.

Bavarder sur Internet

A new model-based approach for power plant Tube-ball mill

2014.4.1 Compared with the Vertical Spindle mills, Tube-ball mills have a much higher grinding capacity. However, there are fewer literatures found in studying Tube-ball mill operation compared with the Vertical Spindle mill. Ma et al. introduced a black box Neural Network model for Tube-ball mills in 2005 [22]. Although the Neural Network can

Bavarder sur Internet

DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR

2019.4.21 The dimensions/areas for a chute should as far as possible be chosen according to. the outlet flange for a machine. The smallest side length in a chute must be min. 5 times the max lump size. Min. chute size for lumpy material: 250mm x 250mm (0,063 m2). Min. chute size for powdery material: ø200 (0.04 m2).

Bavarder sur Internet

Orbis Machinery Ball Mills Learn More

Our combined experience in ball mill design and process equipment development totals more than 60 years and allows us to put a unique spin on steel and lined mills. Ball Mill Drive Options. At Orbis Machinery we

Bavarder sur Internet

A process mineralogy approach to study the efficiency of

2020.12.3 The efficiency of ball mills is about 1.0% and, in some cases, less than 1.0% based on energy consumption. ... Mirmohammadi, M. et al. A process mineralogy approach to study the efficiency of ...

Bavarder sur Internet

Grinding in Ball Mills: Modeling and Process Control

The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and the system for discharging the output product. The size of a mill is usually characterized by the ratio “length to diameter” and this ratio most frequently varies from 0.5 to 3.5. The

Bavarder sur Internet

dosage feeder charbon mill

dosage feeder charbon mill 2021-09-22T14:09:17+00:00 dosage feeder charbon mill. dosage feeder charbon mill myenergycz dosage feeder charbon mill feeder charbon et ball mill Matériel Kefid Machinery feeder charbon et ball mill Chili 120150tph Station de concassage mobile de pierre de rivière Chili 120150tph Station de concassage mobile de

Bavarder sur Internet

Ball Mill SpringerLink

2023.4.30 Ball Mill. Ball mill is a type of grinding equipment that uses the rotary cylinder to bring the grinding medium and materials to a certain height and make them squeeze, impact, and grind and peel each other to grind materials. Ball mill is the key equipment for crushing materials after they are crushed. It is widely used in cement,

Bavarder sur Internet

Ball Mill Design/Power Calculation - 911 Metallurgist

2015.6.19 Ball Mill Power Calculation Example #1. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns). The required product size distribution is to be 80% passing 100 mesh (149 microns). In order to determine the power requirement, the steps ...

Bavarder sur Internet

Articles liés

- Haier Machine À Laver Liste Des Prix Malaisie

- equipo de trituracion primario

- fabricant de la machine de sablage en Nouvelle Caldonia

- mat&233;riau de la tige de broche de broyeur de charbon

- machine de pompage Fer au Rwanda

- fabricants de broyeurs a boulets a sanghai porcelaine

- Le forage mobile équipement de broyage du charbon russe

- matériel d exploitation minière de cuivre en Afrique du Sud

- pour broyeur de pierres prix

- pierre usine de concassage a vidisha mp

- dimensions de la chine cône bol broyeur de cancave

- concasseur primaire pierre en malaisie

- minerai de bauxite fournisseurs indonésie

- la fabrication de materiel de concassage sbm

- Pierre Printemps Cône Pays Série De Concasseur À L Exportation

- moulin à nouveau la dharmesh ptom

- pierre de concassage de la Suède

- Concasseur de rock américain à vendre

- de concasseur à machoires Pdf

- de briques refractaires equipements de concassage

- fabricant d Minerai de fer equipement de criblage de gypse

- karnataka association de broyeur de pierres ao t

- poudre calcaire concasseur

- de table broyeur humide

- machine pierre concasseur en inde

- déchets de construction et de démolition de concassage

- Carrière de pierre fendue Cirebon

- minéraux solides minerai de cuivre

- concasseur à percussion indien machine pierre concasseur

- processus de criblage simple