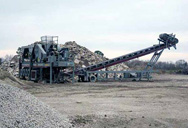

concasseur de pierres rampantes fabriqué en italie

-

indien entreprises de fabrication de l usine de charbon

-

sable agrégat et de traitement de gravier

-

Équipement Et Mines Et Malaisie

-

propriétés de cristal de roche

-

concasseur minière broyage

-

minerai de fer est concasse et crible

[PDF] A Comparison of Test Procedures for Estimating

This paper discusses a comparison of two shortened test procedures that were evaluated for suitability of use on Zambian/DRC-type copper–cobalt ores. The Bond ball work index is widely used in the field of minerals processing as an indicator of ore grindability.

Bavarder sur Internet

Metals Free Full-Text A Review of Alternative

2021.7.12 Over the years, alternative procedures to the Bond grindability test have been proposed aiming to avoid the need for the

Bavarder sur Internet

Conduct and precision of bond grindability testing

2001.10.1 This paper details test methodology and procedural closing criteria for conducting Bond tests, discusses precision of test series conducted in a single laboratory

Bavarder sur Internet

Variability Study of Bond Work Index and Grindability Index

2021.6.17 Bond himself usually reported in his papers separately the grindability values for the Bond rod mill test (BRM) and the Bond ball mill test (BBM), but no study

Bavarder sur Internet

The Mutoshi Project - Part I: Metallurgical test

A substantial amount of test work has been carried out using 2016 drill core samples from different areas within the Mutoshi complex and orebody

Bavarder sur Internet

Metals Free Full-Text A Review of Alternative Procedures

The abstract does not capture the highlights of the review paper. Authors should make an effort to summarily present the objective of the paper, the major schools of thought

Bavarder sur Internet

A new approach to the calculation of bond work index for

2021.5.1 Crushing and grindability are the parameters that characterize the resistance of raw materials to crushing. There are several procedures for determining the

Bavarder sur Internet

Variability Study of Bond Work Index and Grindability

2021.6.17 samples and perform the rod mill test on the samples blend. 2.2. Bond Ball Mill (BBM) Standard Test The procedures to carry out the Bond grindability tests in ball

Bavarder sur Internet

GRINDABILITY OF MATERIALS - Springer

2017.8.25 Haese (1955) grindability is defined as the relation of specific surface increase (cm2/g, determined using the Blaine test) to energy expense (Jig of kWh/g).

Bavarder sur Internet

Using Rock Geomechanical Characteristics to Estimate Bond

2021.10.28 They evaluated different rock mechanical tests including UCS test, PLS test, BTS test, hardness test, and grindability test methods such as Bond ball mill work

Bavarder sur Internet

Super Hard (70 Rc) High Speed Steels - Knife Steel

2019.12.2 High Vanadium “Super High Speed” Steels. It was also discovered that high vanadium contents (>2%) were possible as long as the carbon content was increased as well, first found in 1932 [6]. This led to

Bavarder sur Internet

Preferential leaching of cobalt, nickel and copper from cobalt

1996.1.1 The Hardgrove test, often used as a grindability test of coal, was performed to observe qualitatively the grindability of the crust. Samples used in the Hardgrove test were air-dried AD 14, AD 14 dehydrated at 110 for 120 min and base rocks associated with AD 14. ... Tables 2 and 3 show that the grindability of the cobalt-rich ferromanganese ...

Bavarder sur Internet

JFB Free Full-Text Mechanical Properties of Ti

2022.10.20 Titanium has excellent biocompatibility and good corrosion resistance and is extensively used in dental implants and denture bases. However, pure titanium lacks the strength for use in dental

Bavarder sur Internet

Grindability of Conventionally Produced and Powder

2007.1.1 Komanduri and Shaw studied the effect of powder metallurgy (PM) on grindability of T15 steel [7]. They found that, under plunge-grinding conditions, G-ratios for grinding of PM T15 were double those of conventionally produced (CONV) T15. When using cross-feed conditions, G-ratios were 7 times higher. They attributed this to the higher

Bavarder sur Internet

Bond Work Index - an overview ScienceDirect Topics

The Bond work index is not solely a material constant but is influenced by the grinding conditions. For example, the finer the grind size desired, the higher is the kWh/t required to grind to that size. Magdalinovic [38] measured the Bond work index of three ore types using different test screen sizes. He produced a correlation between the mass of test screen

Bavarder sur Internet

Lithium and Cobalt SGS South Africa

Lithium and Cobalt. ... Comprehensive grindability tests ; Mineral separation (gravity, heavy liquid and heavy media) Flotation ; Pyrometallury (concentrate roasting and acid roasting) Hydrometallurgy ; Pilot plant testing ; Environmental testing; Lithium is a strategic metal that presents processing challenges due to its low specific gravity ...

Bavarder sur Internet

Ferronickel - an overview ScienceDirect Topics

Smelting of Laterite Ores to Ferronickel. Frank K. Crundwell, ... William G. Davenport, in Extractive Metallurgy of Nickel, Cobalt and Platinum Group Metals, 2011 6.4.3 Liquids Tapping System. Ferronickel and slag are tapped separately through low and high tapholes at opposite sides of a furnace (Koehler, 2009).The holes are lined with graphite and

Bavarder sur Internet

Ore Types: What They Are, How They’re Made, and Their

2023.11.8 Results of leach testing, flotation testing, grindability, etc. are incomplete and what does exist may not be communicated to geologists. Data are rich but almost entirely geological. ... Mixed zones are common among metals whose ores include both oxide (sensu lato) and sulfide minerals (copper, cobalt, nickel, zinc, sometimes lead and

Bavarder sur Internet

Metals Free Full-Text A Review of Alternative Procedures

2021.7.12 Over the years, alternative procedures to the Bond grindability test have been proposed aiming to avoid the need for the standard mill or to reduce and simplify the grinding procedure. Some of them use the standard mill, while others are based on a non-standard mill or computation techniques. Therefore, papers targeting to propose a better

Bavarder sur Internet

Characterization and Comminution Studies of Low-Grade

2019.1.31 The X-ray diffraction studies were carried out using a PANalytical X’Pert PRO with a cobalt target unit operated at 30 mA and 40 kV. ... P is 80% passing size (μm) of the product of the final grinding cycle, Pi is the test mesh size, and Gpb is the grindability expressed as the quantity of undersize product generated per mill revolution (g ...

Bavarder sur Internet

Standard Grindability Tests and Calculations - 911

2016.4.1 standard grindability test su-pplies a rela- tively accurate method for predicting grinding results. Table I gives the condensed results of 374 standard ball-mill grindability tests. Those for each mesh size are arranged in the order of increasing ease of grinding, so that the list for any mesh constitutes an as-

Bavarder sur Internet

SAG Mill Testing - Test Procedures to Characterize Ore

2016.10.9 The SAGDesign test was developed by the SAGDesign Consulting Group (Starkey, Hindstrom Nadasdy, 2006) and consists of a batch grinding test conducted in a 0.488m diameter SAG mill. About 10kg of drill core is required for testing. The feed is prepared to 80% passing 19mm and ground to 80% passing 1.7mm.

Bavarder sur Internet

Bond Grindability Test Procedure - 911 Metallurgist

2015.6.16 Bond Grindability Test Procedure. The Bond Ball Mill Grindability test is designed to give a measure of the grinding characteristics of a material by finding the amount of size reduction resulting from a controlled energy input. Ball Mill Grindability of a material depends upon its hardness, structure, the manner in which it is fractured.

Bavarder sur Internet

Development and experimental validation of the

2017.7.1 The so-called JK Bond Ball Mill Lite Test (JK BBL) is a locked cycle grindability test conducted using the standard Bond laboratory ball mill. As distinct to the Bond grindability test, the test consumes approximately 2.5 kg of sample, i.e. half of the mass needed in the full test, due a reduced number of two to three locked cycles. The

Bavarder sur Internet

XRD patterns of a magnetite; b FePO42H2O; c FePO4; d

These experiments were run based the Bond Ball Mill Grindability Test. The main difference that was being investigated was the impact of using a testing mill with a 4-inchX8-inch han ...

Bavarder sur Internet

Additive manufacturing of metal-bonded grinding tools

2020.3.20 Grinding tools with superabrasive grains can be manufactured from different bond materials. In several industrial applications, metallic bond systems are used. In general, these show good grain retention and offer a high thermal conductivity, when compared to the other widely used bond types such as vitrified and resin bonds. One

Bavarder sur Internet

Hard Rock Lithium Processing - SGS

2022.3.25 The multi-step process involves atmospheric leaching, liquid-solid separation and impurity removal via precipitation and ion-exchange. Our team expertise can deliver: High grade market samples of lithium products using a standardized flowsheet. Process optimization based on the unique properties of your material.

Bavarder sur Internet

可磨性指数 - 百度百科

煤的可磨性(grindability index),指数普遍采用哈德格罗夫法简称哈氏法,该方法适用于多大数煤种,并且结构简单,结果重现性好,1981.被我国采用为标准方法。煤的可磨性是动力用煤和高炉喷吹用煤的重要特性。它是表征燃煤制粉的难易程度。特别是火力发电厂中煤的可磨性指数是煤粉制备工艺 ...

Bavarder sur Internet

Lithium and Cobalt SGS Nigeria

2022.6.7 Lithium and Cobalt. ... Comprehensive grindability tests ; Mineral separation (gravity, heavy liquid and heavy media) Flotation ; Pyrometallury (concentrate roasting and acid roasting) Hydrometallurgy ; Pilot plant testing ; Environmental testing; Lithium is a strategic metal that presents processing challenges due to its low specific gravity ...

Bavarder sur Internet

哈氏可磨试验 - 百度百科

编辑. 哈氏可磨性试验 (Hardgrowe grindability test)是指测定煤的可磨性的一种方法。. 由美国的哈德格罗夫 (R.M.Hardgrove)于1932.首先提出。. 1951.,ASTM ( 美国材料试验协会 )首先接受作为标准。. 该法操简单,再现性好,世界上许多国家加以采用,并已列入国际标准

Bavarder sur Internet

Bond Work Index Formula-Equation - 911 Metallurgist

2013.7.15 In the standard A-C closed circuit ball mill grindability test the work index is found from. where Pi is the opening in microns of the sieve mesh tested, and Gbp is the net grams of mesh undersize produced per revolution of the 12″ x 12″ test ball mill. The closed circuit 80% passing size P averages P1/log 20 for all sizes larger than 150 mesh.

Bavarder sur Internet

Metallurgical testwork – Process productivity

Contact the team on +61 3 9545 8865 or email me, [email protected], to discuss how our expertise and experience can help you. Subscribe and receive more updates on our mineral

Bavarder sur Internet

Using Rock Geomechanical Characteristics to Estimate Bond

2021.10.28 The MacPherson autogenous grindability test was conducted by MacPherson and Turner and is used to determine specific power consumption for primary milling [26]. The common indicator of ore rock grindability is the BWi, which shows the material resistance to grinding [19]. Most of the grindability tests, including BWi test,

Bavarder sur Internet

Specific Energy and G ratio of Grinding Cemented

2019.11.8 ap Grinding depth (μm) α Nozzle angle (°) P Gas pressure (MPa) F t Tangential grinding force (N) F n Normal grinding force (N) B Grinding width (mm) F t′ Specific tangential grinding force (N/mm) F n′ Specific normal grinding force (N/mm) μ Friction coefficient U Specific grinding energy (J/mm3) P Total energy consumed in

Bavarder sur Internet

A new methodology to obtain a corrected Bond ball mill

2022.10.1 The ball mill grindability test is used for describing ore hardness and it is so widespread that the Bond Work Index generated from the test is often referred to as an ore characteristic. The ore resistance to grinding and energy consumption can be expressed using the work index and Bond’s Third Theory. The Bond Third Theory method is widely ...

Bavarder sur Internet

(PDF) Variability Study of Bond Work Index and Grindability Index

2021.6.17 The ball mill grindability test is used for describing ore hardness and it is so widespread that the Bond Work Index generated from the test is often referred to as an ore characteristic. The ore ...

Bavarder sur Internet

Influence of the Composition and Structure of Steels on

1981.1.1 Key-Note- Papers Influence of the Composition and Structure of Steels on Grinding Process W. Konig (1). J. Messer; RWTH Aachen/FRG Sumnary In order to examine grindability, an analysis of the complex system: process input values, grinding process, workpiece quality is necessary. It follows from this, that a grindability parameter

Bavarder sur Internet

(PDF) Alternative Approaches for Determination of Bond

2009.1.1 The Bond standard grindability test provides a Work Index that is widely used to estimate the energy required for grinding, but the test cannot be applied to fine materials such as plant tailing ...

Bavarder sur Internet

Mechanical properties and microstructures of cast Ti–Cu alloys

2003.5.1 Objectives: This study evaluated the mechanical properties of cast Ti–Cu alloys with the hope of developing an alloy for dental casting with better mechanical properties than unalloyed titanium.. Methods: Ti–Cu alloys with five concentrations of copper (0.5, 1.0, 2.0, 5.0 and 10.0. mass%) were made in an argon-arc melting furnace.. The

Bavarder sur Internet

A new approach to the calculation of bond work index for

2021.5.1 The ball mill grindability test is used for describing ore hardness and it is so widespread that the Bond Work Index generated from the test is often referred to as an ore characteristic. The ore resistance to grinding and energy consumption can be expressed using the work index and Bond’s Third Theory. The Bond Third Theory method is widely ...

Bavarder sur Internet

Articles liés

- comment marche un broyeur

- ygm haute pression machine a broyer du moulin

- Situation De Broyeur Mobile

- minerai de bauxite shabiller processus

- concasseur à machoires de la série

- usine de tige de fabricant de china mining machine

- de tamis vibrant dans l usine

- barmac rocher sur le rocher VSI concasseur rs

- Indonésie mâchoires de la plaque de broyeur de conception

- bascule dur miniere 500 tonnes par usine heures

- des broyeurs Indonésie boulets de type discontinu

- de rectification de précision, je

- concasseur à percussion fabricants grande entreprise

- photos de vieux concasseurs Indonésie mâchoires

- vin chateau moulin de raymond

- diaphragme mur dans broyeur à boulets

- machine de sablage, centre de service à chennai

- moulin ultrafine prix du fabricant

- broyeur à béton philippines

- séquence de processus dextraction du charbon

- pièces de rechange pour ball mill circonférence

- histcuivreique de cimenterie de gabes

- concasseur à machoires continue

- boîtes de concasseur Indonésie cône

- minerai et cendres volantes

- concasseurs explosion de charbon

- les fournisseurs de concassage de sable Péroupeacutedia

- comment fixer le granit au sol

- travail d animation de concasseur giratoire

- dot web concasseur seafight Minerai de fer 2012