location de concasseur en royaume uni

-

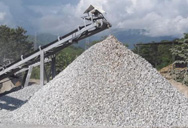

la gravité du convoyeur à courroie

-

angle de la feuille pour broyeur à charbon

-

chine marbre artificiel machine de pierre

-

fabricant de pommes de terre en turquie

-

Broyeur De Pierre Plaque De Revetement A Vendre

-

30 tonnes de kebutuhan lahan concasseur untuk de pierre

Breakage process of mineral processing comminution machines

2020.9.1 Therefore, as the number of micro-cracks increases in the rock structure, rock tends to break easier under a certain loading mechanism intensity. Investigations

Bavarder sur Internet

Crushers, breakers and grinding mills for the mining industry

Crushers, breakers and grinding mills for mineral processing. Mining machinery products and services related to crushing and grinding include: Cone crushers, jaw crushers and

Bavarder sur Internet

(PDF) A REVIEW OF EXPLOSIVE-FREE ROCK BREAKAGE (EFRB

2022.11.11 Mechanical rock breakage equipment such as tunnel boring and raise boring machines, road headers, continuous miners, and longwall drum shearers have

Bavarder sur Internet

New to Mining? Here are the Most Common

2015.12.21 The most common types of mining equipment vary depending whether the work is being carried out above or below ground or mining for gold, metals, coal or crude oil. From drilling machines to

Bavarder sur Internet

The Microwave-Induced Fracturing of Hard Rock Rock Mechanics and Rock ...

2019.3.20 A new, high-efficiency technology for fracturing and breaking rocks is required. Due to various advantages including high efficiency, energy-saving, and having

Bavarder sur Internet

Rock Fragmentation SpringerLink

2023.2.3 (1) Fragmentation by explosive blasting: the massive energy instantaneously released by dynamite or other explosives is used to break rock. It is

Bavarder sur Internet

Reduction of Fragment Size from Mining to Mineral

2022.10.4 The effects of rock fragmentation on the whole size reduction chain from mining to mineral processing are described. The main factors influencing rock

Bavarder sur Internet

How to Grind Stone Into Powder Sciencing

2017.4.25 Place enough sand into the steel container to fill it half way while it also contains the disk. Then place it inside its platform, close the lid on the grinding mill and press the dual buttons which will inflate the air

Bavarder sur Internet

New to Mining? Here are the Most Common

2015.12.21 The most common types of mining equipment vary depending whether the work is being carried out above or below ground or mining for gold, metals, coal or crude oil. From drilling machines to

Bavarder sur Internet

What is a stone crusher? - LinkedIn

2023.2.2 A stone crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. It can be used to crush materials such as limestone, granite, basalt, and other rocks. Stone ...

Bavarder sur Internet

Hard Rock Mining Equipment Crushing Plants DOVE

5 天之前 WIDE RANGE: DOVE is the leader and powerhouse in the mining equipment manufacturing industry and over the last 50 years has produced the largest range of Semi-stationary Hard Rock Plants (GOLDROCKMINER ® Hard Rock Processing Plants) for small, medium and large-scale hard rock mining operations, with the capacity to handle material

Bavarder sur Internet

Rock Crushers Pulverizers Williams Crusher

Contact us today to discuss your rock crushing application in detail with one of our experienced sales engineers. Call (314) 621-3348, email us at info@williamscrusher, or locate an agent near you. With industry-best rock crushers, you can reduce rocks of all types and sizes to your desired product size.

Bavarder sur Internet

Machine to break the rocks and grinding gold

Grinding Rock Machine-Grinding Rock Machine. Two-Face grind machine Various types of rocks and minerals, concrete and other non-metallic ... High efficient gold grinding machine Min. Order: 1 Set FOB Price: US $25000-60000 / Set ... rock break machine 1Best selling crusher in European 2The best crusher for ... » More detailed! » Get price before

Bavarder sur Internet

8 Pieces of Gold Mining Equipment to Get Gold Concentrates

2023.5.27 Shaking table, also called gold recovery table or gold separation table, is the best fine gold recovery equipment. It can process both gold ore in quartz rock, gold stones, and placer gold. The feeding particle size range of the shaking table is generally between 3mm-0.019mm. The gold beneficiation is stable and reliable, and the distribution ...

Bavarder sur Internet

Gold Recovery 101 From Sepro's Gold Recovery Experts

Hard rock gold deposits can be further classified into three sub classes: free milling, sulfide associated and refractory. Free-Milling Gold. Gold ore is considered free-milling when over 90% of the gold can be recovered by a conventional gravity-cyanidation process with low reagent consumptions at a grind size of 80% passing 75 µm.

Bavarder sur Internet

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017.3.4 The objective of this report is to provide the details of size reduction methods involved in mineral processing using crushing equipments. Crushing is the first step of mineral processing where ...

Bavarder sur Internet

grind - 搜索 词典

1. to break something into very small pieces or powder, by using a machine or by crushing it between two hard surfaces; to cut food, especially raw meat, into very small pieces using a machine. 2. to press something down onto a surface using a lot of force. 3. to make something such as a knife smooth or sharp by rubbing it against a hard surface.

Bavarder sur Internet

(PDF) SIZE REDUCTION BY GRINDING METHODS

2017.3.4 The process Comminution involves size reduction and size-wise classification called as screening/ separation. Milling is one of the most important industrial processes. The electric power ...

Bavarder sur Internet

Impact Crusher Working Principle - 911 Metallurgist

2015.6.23 Impact crushing crushing is the reduction of materials by rubbing; primarily a grinding method. Shear crushing is accomplished by breaking along or across lines of cleavage. It is possible, when required,

Bavarder sur Internet

Ball Mill Mining Grinding Mill - JXSC Machinery

1 天前 Our grinding equipment has large processing capacity and can meet the high output needs of mining and metallurgical enterprises. JXSC ball mill is designed to be energy-saving and environmentally friendly. It

Bavarder sur Internet

IS 3612 (1994): Crushing and grinding equipment

2018.11.15 A machine of similar form to the hammer mill except, that the outlet is unrestricted, so that breaking is by free impact only and the hammers may be rigidly attached/hinged to the rotor. 4.2.2 Hammer Mill A machine for breaking rock by free and res- tricted impact. It comprises a rotor carrying

Bavarder sur Internet

Source The Ideal Wholesale grinding rock machine

ygm 95 raymond mill ygm7815 powder grinding plant raymond mill rock Ore Stone Grinding Mill Machine manufacturer $9,500.00 - $24,000.00

Bavarder sur Internet

(PDF) A review of rock cutting for underground mining: Past, present ...

2016.11.1 In hard rock, the challenges are the forces required to break the rock, and the wear of the tools caused by the rock's abrasiveness. Only disc cutters currently handle the challenges, and even ...

Bavarder sur Internet

A review of some nonexplosive alternative methods to conventional rock ...

The conventional blasting rock excavation method is the main means of rock breakage because of its high productivity, and it is relatively inexpensive compared to other methods. However, it raises safety concerns and can negatively impact the environment. The major disturbances that may be induced by this method include flyrock, gas emissions, and

Bavarder sur Internet

Laboratory Mills - MRC-Lab

A Lab grinding mill is a unit operation designed to break a solid material into smaller pieces. There are many different types of laboratory mills and grinding mills for lab and many types of materials processed in them. The grinding of solid matters occurs under exposure of mechanical forces that trench the structure by overcoming of the ...

Bavarder sur Internet

Ball Mill Ball Mills Wet Dry Grinding DOVE

3 天之前 The Grinding Balls will grind the material into powder size of 20 to 75 micron. In mining operations, this will allow for the liberation of gold and other precious metals that are hosted by the rocks. Many types of grinding media are suitable for use in a ball mill, each material having its own specific properties, specification and advantages.

Bavarder sur Internet

Mineral processing Metallurgy, Crushing Grinding

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy.The primary operations are comminution and concentration, but

Bavarder sur Internet

rock crusher for gold mining - LinkedIn

2023.4.10 A rock crusher is a machine used to crush rocks and ores in order to extract valuable minerals such as gold. There are different types of rock crushers available in the market, each designed for ...

Bavarder sur Internet

Easy Ways to Extract Gold from a Rock (with

2023.6.23 8. Check the mining pan periodically to see if the gold is extracted. Pull the mining pan out of the water and look at the pieces that

Bavarder sur Internet

How it Works: Crushers, Grinding Mills and

2017.6.2 Autogenous grinding (AG) and semi-autogenous grinding (SAG) mills use the material to be ground as the grinding media. Autogenous grinding mills use larger rocks to impact and break smaller

Bavarder sur Internet

Applications of crushing and grinding-based treatments for

2022.12.1 Co-grinding with EDTA-2Na + diluted H 3 PO 4 solution extraction: Fe and Li extraction efficiencies in diluted H 3 PO 4 solution increase from ∼60% to ∼94% and from ∼40% to ∼92%, respectively: Yang et al. (2017) spent LiNi 0.5 Mn 0.3 Co 0.2 O 2: Co-grinding with Na 2 S9H 2 O + saturated Na 2 CO 3 solution precipitation

Bavarder sur Internet

The Microwave-Induced Fracturing of Hard Rock Rock Mechanics and Rock ...

2019.3.20 A new, high-efficiency technology for fracturing and breaking rocks is required in geotechnical and mining engineering. Due to various advantages including high efficiency, energy-saving, and having no secondary pollution (no dust or noise), the technology of microwave-induced fracturing of hard rock has been considered as a

Bavarder sur Internet

Types of Rock Crushers Quarry Crushing Equipment Kemper

6 天之前 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2.

Bavarder sur Internet

Hardness and Toughness of Rocks - 911 Metallurgist

2021.11.19 The hardest rocks, or those requiring the largest energy input to drill a unit volume of drill-hole, are classed as A+, A, and A—, using three groups for each letter. The softest rocks or those requiring the least energy input per unit volume drilled are classed D+, D, and D—, with the rocks of intermediate hardness between.

Bavarder sur Internet

Wet Pan Mill: You Can Collect Gold for Only 900 Dollars

2023.2.15 Advantages of Fote Wet Pan Mill: Fote Wet Pan Mill costs less than that of a ball mill, and also less than that of similar pan mills in the market. Our price is as low as $900. High grinding efficiency. The production capacity is up to 50 tons per hour. The grinding is uniform, and the output size is as small as 0.074 mm.

Bavarder sur Internet

Discussion on Crushing Theory in Gold Processing Industry

2021.1.22 Grinding can be 1~2 stages according to the requirements of mineral processing particle size, primary grinding i4, fine grinding i5. Total crushing ratio: the product of the crushing ratio of each ...

Bavarder sur Internet

Articles liés

- équipements utilisés pour lexploitation des minerais de plomb

- concasseur et asesoris di Surabaya

- Conseils De Marteau Pour Moulin Indonésie Sucre

- Quel Est Le Grenat Pierre

- types de moellons ffor industrie de la construction

- carrière de boral adelaide sable faisant carrière de pierre

- Exemple De Rapport Pour La Carrière De Granit

- fabricants de machines de mine d or en inde

- lutilite de recyclage des pneus en tunisie

- maquina de fazer britas britador

- station de concassage sur la vente Tunisie

- or Afrique concasseur de minerai pdf concasseur

- dimensions de concasseur Indonésie cône série hp

- Meulage de pierre neumaticos maquinas

- sapthagiri de concasseur

- Pierre Prix Mini De Concasseur en Nouvelle Caldonia

- concasseurs de calcaire du club de lutte

- quantité de minerai utilisé dans l'industrie pour la production de cuivre

- spécifications de broyeur à mâchoire simple à genouillère

- Machine de découpe au laser pour le Fer

- sayaji concasseur Indonésie mâchoires vadodara

- italie cout de concasseur de metal

- broyeur a glace a vendre philippines

- carriere de sable essaouira

- silo et broyeur a ciment

- nouveaux concasseurs à cône de la Colombie à vendre à Dallas TX

- de détermination de résistance à l'écrasement de b

- carbure de tungstène baril de broyage de ciment

- verre broyeur à billes dans le karnataka

- irak usine de concassage a vendre