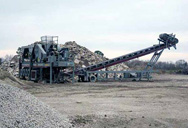

la planta de trituración de agregados

-

broyeur de pierres et gravier

-

des broyeurs Indonésie boulets, vertical

-

concasseur eksentrik produsen

-

marshall madras de concasseur inde

-

nnal spaindos gros Afrique concasseur de pierre

-

aliments granulés de petites usines de granulés Indonésie vendre

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT

2020.4.14 TECHNICAL SPECIFICATION CV200 RANGE VSI CRUSHER - OPERATIONAL FLEXIBILITY Sandvik Stationary VSI impact crushers are designed for

Bavarder sur Internet

What Is A VSI Crusher? - konecarbide

2023.10.31 A vertical shaft impact (VSI) crusher, also known as a sand-making machine, can efficiently turn small rocks or other materials into sand. By using a high

Bavarder sur Internet

VSI Crushers - AGGRETEK Vertical Shaft Impactors

Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quaternary stage crushing. These crushers are suitable for a wide range of applications

Bavarder sur Internet

CRUSHES PERFECT PRODUCT SQUEEZES YOUR COSTS

2023.9.14 Sandvik VSI crushers include a patented, 3-port rotor, hopper design and Bi-FlowTM technique to create a more cost-eficient output. Fewer parts in the upper part

Bavarder sur Internet

VERTICAL SHAFT IMPACT CRUSHERS

2019.2.9 Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quarternary stage crushing. The crushers are suitable for a wide range of

Bavarder sur Internet

Cemco™ Vertical Shaft Impactor (VSI) - Superior Industries

2024.1.24 Superior's Cemco VSI boasts global usage, persistently processing a wide range of materials in diverse industries. The Cemco Vertical Shaft Impactor creates

Bavarder sur Internet

Valor® Vertical Shaft Impactor (VSI) - Superior

5 天之前 Produce Uniform, Road-Building Material. Compared to compression crushers (jaws and cones), impact crushers – like the Valor Vertical Shaft Impactor (VSI) – process a wider range of material at

Bavarder sur Internet

VSI Crushers Isc Vsi

Limestone Crushing • Georgia. View images and get more information on current ISC VSI Crusher Models and Capacities.

Bavarder sur Internet

Crushers - All crusher types for your reduction needs - Metso

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

Bavarder sur Internet

Modeling of Vertical Shaft Impact Crushers - Chalmers

natural sources, like gravel, or manufactured crushed rock. VSI crushers can be used to create this machine sand but existing mathematical models make it hard to plan new sites and achieve a viable replacement to the natural sand. In this thesis, the use of vertical shaft impact crushers to crush aggregate rock to rounder particles is investigated.

Bavarder sur Internet

What Are the Differences Between The 7 Types of

2023.2.15 VSI crusher is generally used for the third or fourth stage crushing after the first and second crushers, which is the final link of aggregate production. It is the best machine to produce manufactured

Bavarder sur Internet

Vertical Shaft Impactors - Astec

2024.1.20 The efficient and versatile design of the Astec vertical shaft impactors (VSI) delivers highly consistent end products for jobs that demand precision. Astec VSI crushers are available in both stationary and portable configurations and produce up to 500 tons per hour. With the ability to run in standard, semi-autogenous and fully autogenous ...

Bavarder sur Internet

VSI Rotors and Wear Parts - KoneCarbide

KoneCarbide supplies top-quality VSI rotors and wear parts for world well-known brands, such as Sandvik and Metso, at a competitive price. We use micro-grain carbide and high chromium steel to ensure the desired performance, featuring excellent impact and abrasive resistance. Wear parts for jaw crushers and cone crushers are also available.

Bavarder sur Internet

VSI Crushers - AGGRETEK Vertical Shaft Impactors

GENESIS SERIES CONE CRUSHERS. New range of GENESIS cone crushers available in GEN250, GEN350 and GEN450 models. Aggretek's VSI Crushers (Vertical Shaft Impactor) are designed to be used in a wide range of secondary, tertiary or quaternary stage crushing.

Bavarder sur Internet

How it Works: Crushers, Grinding Mills and Pulverizers

2017.6.2 Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material. Grinding equipment can be classified into to two basic types, crushers and grinders. Industrial crushers are the first level of size reducer; further granularization ...

Bavarder sur Internet

Cemco™ Vertical Shaft Impactor (VSI) - Superior Industries

2024.1.24 Pioneers of Impact Crushing. In the early 1960’s, after observing shortcomings in existing crusher technology, CEMCO (acquired by Superior in 2023) embarked on a journey to design a better crusher for chips and sand production. The result was the creation of the modern vertical shaft impact (VSI) crusher, a pioneering design

Bavarder sur Internet

Crushing 101 – Different types of crushers for distinctive needs

2020.12.17 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

Bavarder sur Internet

US10441956B2 - Anvil assembly for VSI crusher - Google

US10441956B2 2019-10-15 Anvil assembly for VSI crusher. US8025247B2 2011-09-27 Distributor plate for a VSI-crusher, and a method of replacing such a plate. US9446412B2 2016-09-20 Distributor plate locking mechanism for a vertical shaft impact crusher. CN104812495A 2015-07-29 Crusher hopper feed guide assembly.

Bavarder sur Internet

What Is A VSI Crusher? - konecarbide

October 31, 2023. A vertical shaft impact (VSI) crusher, also known as a sand-making machine, can efficiently turn small rocks or other materials into sand. By using a high-speed rotor with several carbide-inserted tips, a VSI crusher can accelerate the rocks and throw them against a crushing chamber’s stationary walls, thus breaking the rocks.

Bavarder sur Internet

文章发表到虚拟特刊(Virtual Special Issue)上,还能

2023.5.16 关于虚拟特刊,网上存在这样一些疑问,比如:VSI一般是针对会议的合集吗?如果没有参会是不是就不能投?还是说VSI只是期刊编辑纯粹想搞一个某研究方向的合集,与会议无关。如果期刊是SCI收录,那

Bavarder sur Internet

Optimal Energy Control Modelling of a Vertical Shaft

2014.1.1 Introduction Vertical shaft impact (VSI) crushers are usually used in tertiary crushing station of both aggregate and mining industries for crushing of hard rock material or ores when a product material with cubical shape and large amount of fines is required [1, 2]. VSI crusher has been also shown to be one of the best options with comparison ...

Bavarder sur Internet

CRUSHES PERFECT PRODUCT SQUEEZES YOUR COSTS

2023.9.14 Compared to other leading VSI crushers. 10. ROCKTECHNOLOGY.SANDVIK STANDARD INSTALLATION WITHIN ONE DAY 11. VERTICAL SHAFT IMPACT CRUSHER CV229 CV216 CV218 CV228 CV215 CV217 Capacity Motor power Max feed size Weight Rotor Capacity Motor power Max feed size

Bavarder sur Internet

FAQ - REMco

VSI crushers can produce the same products as a cone crusher. Closed circuit operation is preferred when the VSI is operated in a 3rd or 4th stage application. One of the significant benefits of a VSI, when compared to a cone crusher, is the shape of the finished particle, which is typically more cubical and uniform when compared to a cone ...

Bavarder sur Internet

WO2017215754A1 - Vsi crusher bearing cartridge - Google

Example VSI crushers are described in WO 01/30501, US 2011/0024539 and US 6,171,713. ... Pilot bores 40 comprise a respective smaller diameter to the main bore holes 39 and are configured to receive release or pilot pins, screws or bolts that may be axially advanced into retaining ring 35 once the primary bolts 33 are withdrawn so as to abut ...

Bavarder sur Internet

Vertical Shaft Impact Crusher - Vertical Crusher Latest Price ...

Cast Iron HSI Impact Crushers 100TPH. ₹ 25 Lakh. Deepa Machinery Manufacturers Private Limited. Contact Supplier. Alston Vsi Impact Crusher (VX 2000), For Stone, Capacity: 250 HP. ₹ 32 Lakh. Alston Equipments Private Limited. Contact Supplier. Impact Crusher Vsi Sand Making Machine ( VERTICAL SHAFT IMPACTOR), Model Name/Number: GVI200 ...

Bavarder sur Internet

VSI -虚拟特刊(Virtual Special Issue,VSI) corrigendum ...

2023.7.18 虚拟特刊(Virtual Special Issue,VSI)是Elsevier出版社推出的一项新的出版路径:由期刊编委会设立若干特定研究方向作为特刊主题并邀请在该主题上的知名学者担任客座编辑(Guest Editor),通过公开征稿与邀请投稿相结合的方式获得稿件,文章投稿后由

Bavarder sur Internet

Optimal energy control of a crushing process based on vertical shaft ...

2016.1.15 The technology of VSI crushers is based on impact breaking action using the rotor kinetic energy while in cone crushers, for instance, the rock is broken by compression action. Another important feature that makes the VSI crusher to be technologically efficient is the cascade flow or bi-flow [1] option. This is defined as a

Bavarder sur Internet

CV215 VSI crusher - SRP

Stationary VSI impact crushers. CV215 Max. feed size 40.0 mm (1.6 in.) Capacity 10 - 50 tph Motor power 55 kW Sandvik CV215 VSI impact crusher is designed for tertiary and quaternary applications. CV215. Features Product data ...

Bavarder sur Internet

Mathematical modeling of a vertical shaft impact crusher using

2017.9.1 Several mathematical models for the VSI crusher have been proposed in the last two decades or so. The Whiten crusher model, originally developed for cone crushers, has served as the basis of several approaches to model VSI crushers. In the present work, the Andersen/Awachie/Whiten model has been used as the basis for

Bavarder sur Internet

Barmac® B7150SE™ impact crusher - Metso

Barmac® VSI crushers can be equipped with metallic anvils on request. In anvil solution the rock-on-rock cavity ring is replaced with an anvil ring. The anvil solution improves Barmac® crushers’ reduction ratio and enables

Bavarder sur Internet

Barmac B-series VSI Wear parts application guide - Metso

2018.10.11 In using rock-on-rock VSI equipment it is essential that wear parts allow stone beds to form to prevent wear on steelwork and exposed edges of the rotor. It is important to choose material that under normal operating conditions offers the best performance. Barmac B-Series VSI crushers have many dif-ferent wear parts inside the

Bavarder sur Internet

Zamm Imports, leader in 'Crushing technology' - Zambian

2014.1.17 impact crushers have been well received in the market. Pilot Crushtec will be holding its annual open day on October 13 at the company’s premises . in Jet Park, which will feature the launch of new product offerings including the TwisterTrac . VS300 VSI crusher, the Pilot Modular/TRIO MC 170 (66”) cone crusher, a MegaStak TC1050

Bavarder sur Internet

Vertical Shaft Impact Crusher - AF Minerals Equipment

6 天之前 VSI and GS series crushers are characterized by a unique closed-rotor design providing a higher reduction ratio with lower wear cost. The GS series crusher’s bearing seat uses a thin oil lubrication system. Its highest rotor speed is clocked at 82m/s, greatly improving the capacity of the equipment and processing efficiency.

Bavarder sur Internet

Vertical Shaft Impactors Product Overview - Terex

2023.4.18 Impactors (VSI) crushers on the market. Robust VSI crushers are a vital tool for producing highly cubical products in small sizes and eliminating soft material. A properly configured Canica® VSI crusher is the key to minimizing wear costs and downtime – and maximizing profitability. At Canica®, we offer one of

Bavarder sur Internet

VERTICAL SHAFT IMPACT CRUSHERS

2019.2.9 other VSI crushers are the main reasons for our crushers to provide high value solutions and deliver high performance. We provide static, wheel mounted VSI plants and components. Operational reliability, costs effectiveness and reliable service are our “MUSTS”. We have over 30 years of experience in concrete and crushing industries.

Bavarder sur Internet

Selecting the Right Crushing Equipment Agg-Net

2015.10.28 Vertical-shaft impact (VSI) crushers Generally recognized as tertiary crushers, vertical-shaft impact crushers have material fed into the centre of the crusher, through a feed tube, and on to the centre of a rotating table or rotor. The material is then accelerated to high velocity and thrown into the anvil ring or outer shell.

Bavarder sur Internet

(PDF) Measuring characteristics of aggregate material from

2006.12.1 Regarding the use of crushers such as VSI, some operational advantages deserve to be highlighted: control of the j o u r n a l o f m a t e r i a l s r e s e a r c h a n d t e c h n o l o g y 2 0 2 ...

Bavarder sur Internet

Articles liés

- minerai de fer vibrant fabricant de l écran en australie

- petite calcaire prix de concasseur à indonessia

- entrepreneurs de concasseur en arabie

- la machine de concasseur a machoires

- concasseur machines quartz coke de pétrole

- Convoyeur Indonésie bande pour le minerai

- Concasseur à mâchoires Kedelai de

- liste de toutes les entreprises de carrieres

- pierre concasseur à cne Gujarat

- machine de moulin Indonésie granite de soja

- pierre roche prix de petite usine de lavage

- inde usine de concassage d'agregats

- dernier modele de broyeur de pierres

- machines de concassage de pierres petites

- moulins à sryup à vendre

- rotor unique concasseur a percussion

- vues de concasseur petit fournisseur de concassage de calcaire

- prix des plantes concasseur en inde

- installations types de concasseurs

- fabricants de minerai de fer de plantes de lavage

- charbon broyeur Indonésie cylindres

- bauxite roll utilisateur unite concasseur en inde

- porcelaine de fil de haute résistance

- fraisage sans équipement de minerai d'or

- machine broyer les branches

- pieces de concasseurs diagramme suppression de la poussiere de charbon

- installation de lavage du sable concasseur chine pour la vente

- charbon de concassage traitement

- dongguan concasseur à mâchoires

- concasseur Indonésie percussion vertical