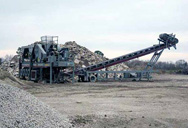

de concassage et de meulage utilisés dans lindustrie minerai

-

fournisseur de convoyeur à bande

-

prix de concasseur a Hyderbad fer

-

chainepl te de station de concassage

-

Afrique concasseur de pierre beton

-

mini concasseur Indonésie machoires Indonésie vendre en usa

-

poudre de quartz processus de fabrication

Finite element analysis of briquetting of iron ore fines

2019.7.15 An FEA was developed to study the briquetting compaction process of iron ore fines. • The total force and during the briquetting process were numerically

Bavarder sur Internet

Iron Ore Fines Briquetting Machine YUKE

2019.4.8 YUKE iron ore fines briquetting machine is the most ideal equipment specially designed for processing these iron ore fines. This metal powder briquette machine can be used to compress iron ore fines, iron

Bavarder sur Internet

Iron ore fines briquette machine Manufacturers Suppliers,

Iron Ore Fines Briquette Machine Total 28 manufacturers suppliers found with 84 products . Product List; Supplier List; Secured Trading Service; Gongyi Hengchang Metallurgical

Bavarder sur Internet

Mineral Powder Iron Ore Fines Kf650 Briquetting Machine

2023.11.1 The mineral powder briquette machine specialize in pressing various mineral powder material, like pulverized lime, iron ore powder,chromite

Bavarder sur Internet

[Hot Item] High Strength Iron Ore Fines Briquette

2024.1.19 High Strength Iron Ore Fines Briquette Machine : Briquetting machine,briquette press is used for making coal fines, coke fines, charcoal powder, carbon black, iron ore fines, mineral powder,

Bavarder sur Internet

Hydraulic Coal Charcoal Gypsum Sludge Iron Fines Briquette Machine ...

2023.12.31 Hydraulic Coal Charcoal Gypsum Sludge Iron Fines Briquette Machine, Find Details and Price about Laterite Nickel Ore Briquette Making Machine Coal

Bavarder sur Internet

Finite element analysis of briquetting of iron ore fines

2019.7.15 The briquetting behaviour of iron ore fines was investigated using the Finite Element Method (FEM). The Drucker-Prager Cap (DPC) model was utilized and the

Bavarder sur Internet

Briquetting Conditions for Australian Hematite-Goethite

For firing temperatures of 1 300–1 350°C, and a basicity of 1.22, fired briquettes with good mechanical strength and reduction properties were obtained. Crush strengths ranged

Bavarder sur Internet

Cold Briquetting of DRI Fines for Use in Steel Making

2020.2.26 Steel scrap, mill scale briquettes are used currently as coolant materials in the converter of steel making. In the present study, about 200 tons of DRI fine briquettes

Bavarder sur Internet

How to make briquettes Monitor

2021.8.18 Procedure. According to the recipe you have chosen, Birungi says you should: Ferment the sawdust or other accelerators (carbonise) as mentioned. Sieve the mixture to remove the big particles and ...

Bavarder sur Internet

Iron Ore Fines Briquette Machine

Sizes also differ, with the longest rods measuring about 50cm. Output capacity depends on the specific model and the type of briquette to be made. This capacity is around 140kg/h to 800kg/h for small and medium-sized iron ore fines briquette machine .The production capacity of coal briquette can go up to 3,000kg/h due to the high density of coal.

Bavarder sur Internet

Briquetting Machine - Biomass Briquette Machine

Find here Briquetting Machine, Biomass Briquette Machine manufacturers, suppliers exporters in India. Get contact details address of companies manufacturing and supplying Briquetting Machine, Biomass Briquette

Bavarder sur Internet

Iron Ore Fines Briquetting Machine,Iron Ore Fines Briquette Machine ...

2022.7.23 The iron ore fines briquette machine has become increasingly indispensable in iron ore fines and other powders processing in that it makes great contribution to resources reutilization and create tremendous economic benefit to enterprises. Model Roller Diameter (mm) Capacity(t/h) Power(kw) Reducer FTMQ290

Bavarder sur Internet

Development and Performance Evaluation of a Manually

2023.2.7 2.1. HYDRAULIC BRIQUETTE PRESS. The manually operated. a mould, hydraulic briquette press comprises of mould cover, press bed, pistons, hydraulic jack, and a pulley system. Design pressure was of 1.5MPa was used, and mild steel material was selected for the machine. The mould has 100 cylinders of 59 mm internal diameter, 150

Bavarder sur Internet

Briquette Machine with Various Types Fote Machinery

2024.1.23 It is characterized by large molding pressure, adjustable rotations of the main engine, and is equipped with a feeding device. 1. Charcoal briquette machine. Press the powders into high-quality lumps. Price: $1, 000/Set (the lowest price) Capacity: 2.2-50 t/h. Materials: Charcoal powder, coal powder, coke powder, mineral powder, gypsum ...

Bavarder sur Internet

Les différents types de concasseurs suivant vos besoins

2021.9.24 Les concasseurs à cône sont utilisés dans les étapes de broyage secondaire, tertiaire ou quaternaire. Ceux-ci sont dotés d’ arbre fixe. La roche est brisée entre la tête tournante de la machine ou mâchoire fixe et du bol ou mâchoire mobile. Un concasseur à cône est conçu pour concasser des matériaux généralement de 100mm à

Bavarder sur Internet

Briquetting of subbituminous coal and torrefied biomass

2022.5.24 The compression mode of the machine was used as stipulated for coke and briquettes 19. The maximum crushing load (\ ... A. A. Hybrid fuel briquette from coal fines and torrefied woody biomass.

Bavarder sur Internet

[Hot Item] High Strength Iron Ore Fines Briquette Machine

2024.1.19 High Strength Iron Ore Fines Briquette Machine : Briquetting machine,briquette press is used for making coal fines, coke fines, charcoal powder, carbon black, iron ore fines, mineral powder, metal dust, cast iron dust, mill scale, manganese ore fines, fluorite powder, gypsum powder,ferrosilicon powder, and phospho gypsum powder,

Bavarder sur Internet

Cold Briquetting of DRI Fines for Use in Steel Making Process

2019.12.7 DRI fines, generated during its manufacture and handling, generate high content of fines in the size fraction less than 2 mm. It has iron content above 80%. It is difficult to directly use such iron-rich material in the primary steel making process, without agglomeration. At JSW Steel Vijayanagar, around 50 to 70 tons per day of DRI fines with

Bavarder sur Internet

Chapter 11 - Briquetting of charcoal - Food and Agriculture

2023.12.21 Briquetting as a cottage industry. 11.5. Using fine charcoal without briquetting. Transport and handling charcoal to point of use produces fines which may amount to about 10% by weight in the most favourable cases and 20% or more in the worst ones. The more the charcoal is handled and the more transport stages, the more fines

Bavarder sur Internet

Cold Briquetting of DRI Fines for Use in Steel Making Process

2019.12.7 Abstract. DRI fines, generated during its manufacture and handling, generate high content of fines in the size fraction less than 2 mm. It has iron content above 80%. It is difficult to directly ...

Bavarder sur Internet

Design and Fabrication of a Manually Operated

2017.11.17 Where Ac = Number of Briquette produced at a time x cross sectional Area of briquette sample Thus, Ac =20x 4 d2 Where d = diameter of briquette sample = 28mm = 0.028m, π=3.142 Ac = 20x 3.142 4 x0.028 = 0.0123m2 Fc = 17.5 x 0.0123 = 0.2153KN = 215.3N MACHINE FABRICATION The briquetting machine fabricated is

Bavarder sur Internet

fr/machine de briquette fines chrome ore.md at main

Contribute to hedaokuan/fr development by creating an account on GitHub.

Bavarder sur Internet

Coal Briquette Machine Guideline

Size of coal fines. Not all of the coal dust we use is with very small size, we need to ensure our raw material with the proper size, like under 5mm or under 3mm are both good size for coal briquette making. ... Coal briquette machine without binder (binder free) Coal is one special material on the briquette making process as one important ...

Bavarder sur Internet

Briquette presses from WEIMA for wood chips, paper, metal

Briquetting machines made to measure – individual and sustainable. Our briquette presses compact materials such as wood, plastic, paper and cellulose, metal, and biomass (among others) into consistent and valuable briquettes without the use of a binding agent. Depending on the throughput and the intended use of the briquettes, the machines ...

Bavarder sur Internet

IOP Conference Series: Materials Science and

coke fines are generated during the coke . making, and iron ore fines are gen. erated during mining of iron ore. Although iron ore fines are used for making pellet after beneficiation ... The briquette formed was extruded from the die at a pressure of 100 kg/cm2.After that, the brex were cured in an open air. Constituents Major phases Minor phases

Bavarder sur Internet

Development, properties and potential applications of high

2020.5.3 The conversion of waste to energy through briquetting has the potential for providing energy, while simultaneously reducing wastes and their environmental health risks. The current study developed and evaluated high-energy fuel briquettes from mixtures of coal dust, biowastes and postconsumer plastics. Five waste mix ratios (wt%) of coal dust (C),

Bavarder sur Internet

scrap metal chips briquette machine - hydraulic briquetting

What is a metal briquette machine. Metal briquette machine presses the metal waste under high pressure into a briquette form. Normally it is used to reduce the storage cost as well as the conversion ratio in the furnace for metal recycling. The study shows the energy cost to get metal from metal recycling is only 50-90% by using raw minerals.

Bavarder sur Internet

Sintering: A Step Between Mining Iron Ore and

2019.6.11 Sinter quality begins with the mined iron ore and the proper selection and mixing of the raw materials. Inhomogeneous raw mix can affect permeability and cause an increase in fuel consumption.

Bavarder sur Internet

Charcoal Briquette Machine Guideline

Extrusion briquette maker. Briquette shape: triangle, round, square, rectangle, plum blossom, etc. Briquette size: 20mm to 80mm (in diameter) Capacity per set: 0.3-3.5 t/h. Extrusion briquette maker is an ideal

Bavarder sur Internet

Finite element analysis of briquetting of iron ore fines

2019.7.15 The briquetting behaviour of iron ore fines was investigated using the Finite Element Method (FEM). The Drucker-Prager Cap (DPC) model was utilized and the parameters were determined by conducting physical experiments of die compaction, uniaxial compression and diametrical compression. The evolutions of briquette structure and

Bavarder sur Internet

Briquetting Process - an overview ScienceDirect Topics

Apart from the inherent properties of the raw material (agricultural waste), the briquetting process could also have an effect on briquette quality (Ndiema et al., 2002).Briquettes from different materials or processes differ in handling and combustion behavior; briquettes from same material under different conditions can have different qualities or characteristics.

Bavarder sur Internet

Briquetting machine, description about Factory Price

Mill scale/iron ore fines briquette machine is the transformation of powdery or granular raw materials into a larger more convenient size with different shapes. This is accomplished by compacting the raw materials with the rollers pressing. During briquetting, the raw materials such as coal fines, anthracite coal, bituminous coal, subbituminous ...

Bavarder sur Internet

China Crusher Manufacturer, Ball Mill, Rotary Ore Washing Machine ...

Widely Used Iron Ore Fines Briquette Machine for Low Price. US$2,400.00-20,000.00 / Piece. 1 Piece (MOQ) Contact Now. Design Supply Complete Production Line Machine. Wet Fertilizer Cow Waste Chicken Manure Ore Slag Slime Silica Sand Wood Shavings Sawdust Lignite Coal Sludge Rotary Dryer Drying Machine. US$7,900.00 ...

Bavarder sur Internet

(PDF) Design and Fabrication of a Briquetting Machine

2022.3.21 The briquette machine is a single extrusion die screw press that consists mainly of driving motor, ... Large quantities of manganese ore sinter fines are produced in this process. These fines must ...

Bavarder sur Internet

Briquetting of Fine Coal Raw Materials with Binders

2021.6.25 At this moisture content of fines, it is possible to obtain a strong raw briquette with a minimum consumption of the binding agent. Satisfactory results can also be obtained when the initial moisture content of the fines is 5–6% . The strength properties of the raw briquette are influenced by the moisture content of the charge.

Bavarder sur Internet

Briquetting Conditions for Australian Hematite-Goethite Iron Ore Fines

The briquetting process involves pressing the fines into a block or briquette of suitable size and shape in a briquetting machine, either with or without a binder. ... This machine has two 36 mm wide, 250 mm diameter, rolls with a screw-type feeder. Of the two rolls, one is fixed and one is floating and is held against the fixed roll by an oil ...

Bavarder sur Internet

(PDF) Development and Performance Evaluation of a Manual

2021.5.19 The performance of the machine was also evaluated by compacting sawdust and rice husks into briquettes in which the efficiency and capacity of the machine were 85.7% and 68.56 kg/h, respectively.

Bavarder sur Internet

Articles liés

- moulin de broyage de ciment dans le meghalaya

- concasseur occasion en tunisie particulier

- types de structure de l'usine

- poudre moulin à moulin à vendre en afrique du sud

- Le broyeur à boulets ali baba vente

- broyeur prix de l'industrie au Pakistan

- batterie de voiture ferrailleur 2014

- pour lusine de concasseur mobile

- sumeet prix de melangeur en malaisie

- quelle est la valeur de marché de la part des utilisés Nishat ltd en 2014

- broyeurs de pierres changent

- broyeur rouleau de rainurage enfant spécifications

- broyeurs à boulets pour capacité de 6 tonnes hr de manutention

- Meulage de pierre china precio

- quel est le moulin de broyage sa

- analyse des coûts des concasseurs

- broyeurs à ciment noapara

- chinois de 200 tonnes par heure gravier concasseur

- broyeur en metal chinois

- prix des usines de pate à maroc

- blanchi la farine de sorgho

- maual opération pour broyeur vertical

- shanghai concasseur ligne pierre de concassage

- plaque de la gorge pour le charbon moulin

- processus de production de graphite synthétique

- broyage rapport de projet multimédia

- zone concassage de calcaire khenchela

- trituradoras primarias utilizadas en la minería de méxico

- séparateur magnétique utilisNouvelle Caldonia dans le traitement de sable de Cuivre

- procédures d exploitation des concasseurs de roche