du minerai de fer en fe oxyde

-

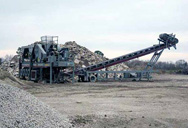

movil Meulage de pierre potencia

-

cout de concasseur de pierre plante

-

étude de faisabilité du concasseur usine en arabie saoudite

-

a l interieur du travail de broyeur a boulets

-

de pierre concasseur pièces et machines ajustement de

-

Systeme de nettoyage de zenith a vendre

Horizontal vs. Vertical Milling Machines: What’s the Difference?

5 天之前 Since we just pointed out how expensive horizontal mills can be, you’ve probably guessed that when it comes to the choice of horizontal vs. vertical milling machine,

Bavarder sur Internet

Horizontal vs Vertical Milling: What’s the Difference?

2019.8.22 While vertical milling machines usually have long and thin cutting tools, horizontal milling machines have shorter and thicker cutting

Bavarder sur Internet

Horizontal vs Vertical Milling Difference

2021.1.21 The shape and specifications of milling cutters and tools for the two types of machines are different. Horizontal milling machines feature short and thick tools capable of removing large amounts of

Bavarder sur Internet

Horizontal vs. Vertical Milling and Turning: What

2020.1.24 The two mill types have different components and are suited to different cutting operations: as a rule of thumb, a horizontal milling machine can cut deep grooves with minimal tool chatter or deformation,

Bavarder sur Internet

Vertical Mill vs Horizontal Mill - Difference Between ... - Junying

2021.8.20 Difference Between Horizontal and Vertical Milling Machine - Vertical Milling vs Horizontal Milling. A horizontal milling machine usually consists of the base,

Bavarder sur Internet

Vertical vs. Horizontal Milling Machine: Which Should I Use?

2021.7.16 Time: If you are using a milling machine to complete daily tasks or for a long-term project that requires a regular, fast turnaround time, a horizontal milling

Bavarder sur Internet

Vertical vs. Horizontal Milling Machines - Fusion

2021.2.1 Vertical vs. Horizontal Milling Machines: Advantages and Disadvantages. Because of their configuration, horizontal mills have much better chip evacuation, as gravity allows them to fall. This results in a

Bavarder sur Internet

An Overview of Vertical vs. Horizontal Milling - Precise Tool

2018.9.9 An overview of the differences and advantages of vertical milling compared to horizontal milling follows. How a Vertical Milling Machine Works. When used to

Bavarder sur Internet

Horizontal Boring Mills vs Vertical Boring Mills: Which is

2023.9.7 Advantages: Space-Efficient: Vertical boring mills have a smaller footprint compared to horizontal ones, making them a good choice for workshops with limited space. Ease of Setup: Setting up a workpiece on a vertical boring mill is often simpler and more straightforward, as the workpiece is typically held on a vertical table.

Bavarder sur Internet

Horizontal vs Vertical Milling Machine - Which

2023.3.1 Horizontal mills can remove more materials at a faster rate because of their stability and their capacity to make deeper cuts. In comparison, vertical mills have a lower material removal rate. Machine

Bavarder sur Internet

Types of Wind Turbine: Horizontal Axis Vertical

2023.8.25 Horizontal axis wind turbine (HAWT) Vertical axis wind turbine (VAWT). #1 Horizontal Axis Wind Turbine Generator . ... Both multi-blade and sail-type mills run at speeds of 60 to 80 rpm. The propeller

Bavarder sur Internet

Buyer's Guide to Loopers in Steel Rolling Mills - Steefo

Our focus on technology and innovation also provides you with the most up-to-date loopers for your rolling mill. To learn more about the Steefo Group and their products and how they can improve your productivity and profits, contact +91 98240 76873 or drop a mail at marketing@thesteefogroup. horizontal loopers, Loopers, Rolling Mills ...

Bavarder sur Internet

What Is a Knee Mill How Do They Work? [Full Guide]

2023.2.28 A knee milling machine is a form of standing machine that is rather straightforward. It can move along the vertical Y-axis and the horizontal X-axis. In other words, the worktable travels along the machining axis exactly like the workpiece itself. Bridgeport mills are another name for knee mills on occasion.

Bavarder sur Internet

Vertical vs. Horizontal Milling Machines - Fusion 360 Blog

2021.2.1 Vertical vs. Horizontal Milling Machines: Advantages and Disadvantages. Because of their configuration, horizontal mills have much better chip evacuation, as gravity allows them to fall. This results in a more refined surface finish and also prolongs tool life. “When you’re machining a part with a deep cavity or pocket, all the chips you ...

Bavarder sur Internet

Types of Wind Turbines: Horizontal vs. Vertical Axis

Key Differences between HAWTs and VAWTs. While both types of wind turbines serve the purpose of harnessing wind energy, there are notable differences between HAWTs and VAWTs: Design: HAWTs have a horizontal rotor shaft and blades facing the wind, whereas VAWTs have a vertical rotor shaft and blades spinning around it.

Bavarder sur Internet

Vertical Axis Wind Turbines vs Horizontal Axis Wind Turbines

2009.11.10 A vertical problem, but easily solved vertically. Without chemical batteries. Compressed air will drive a small horizontal turbine, (like a jet engine. It is being done right now). 4) Horizontal wind turbines rotate so fast, birds and bats can not see them. Vertical turbine motion is in a very small field that avian creatures can see them and ...

Bavarder sur Internet

Choosing the Right Milling Machine: A Comprehensive Guide to Horizontal ...

2023.11.8 Horizontal Mill: Vertical Mill: Orientation : In horizontal milling machines, the spindle, carrying the cutting tool, is positioned horizontally. The rotary cutter cuts into the surface and removes material from the workpiece while revolving around this horizontal axis. In a vertical mill, the tool is set in a vertical orientation.

Bavarder sur Internet

Should You Choose a Horizontal or Vertical Machining Center?

2023.8.18 HMC’s tend to be more expensive than VMC’s. Actually much more expensive. On average HMC’s cost $375K whle VMC’s cost $115K. As a result, 4 times as many VMC’s are sold vs HMC’s every year. Since there are so many more VMC’s, many fewer machinists, operators, and shop owners have experience with HMC’s.

Bavarder sur Internet

Boring On a Mill Machine: A Complete Tutorial

2024.1.8 As you probably know, there are two types of boring machines: vertical and horizontal boring mills. They mainly differ in orientation and whether the boring heads remain stationary. Check out

Bavarder sur Internet

Guide to selecting vertical or horizontal feed mixers

2023.3.7 New feed mills, especially ones that operate at farm level (home mixing) are built every day, whereas older facilities keep being updated, especially those that pass from the analogue to the digital era.. The perennial question whether a vertical or horizontal mixer is better, or more economical for the short or long run, remains as strong as ever. .

Bavarder sur Internet

Horizontal vs. Vertical CNC Machines: What Are the

2022.3.29 A horizontal milling machine, also known as a horizontal machining center or HMC, features a cutting tool that is oriented horizontally. Their horizontal design allows chips to fall away naturally and safely, which helps to achieve smooth, quality finishes. HMCs are most commonly used for larger volume jobs and have more machining power

Bavarder sur Internet

Vertical Pellet Mill VS Horizontal Ring Die Pellet Mill

2022.10.2 The rotating speed of the horizontal ring die pellet machine is more than 200rpm, while the rotating speed of the vertical ring die is 75rpm. It is like the torque of a car, when the speed is fast, the torque is small, and when the speed is slow, the torque is large. The woods in South and Southeast Asia are hardwoods and require high-torque ...

Bavarder sur Internet

Vertical Mill vs Horizontal Mill - Difference Between ... - Junying

2021.8.20 Cost. Generally, a vertical mill is cheaper in price when compared to a horizontal mill. 4. Surface finish. A horizontal milling machine offers a better surface finish. 5. Efficiency. Horizontal milling has a higher material removal rate at the same tool speed in the same amount of time. 6.

Bavarder sur Internet

Horizontal vs Vertical Milling: What’s the Difference?

2019.8.22 Horizontal milling machines are able to perform heavier, deeper cuts than vertical milling machines. As a result, manufacturing companies often use them to cut grooves or slots into workpieces. Hopefully, this gives you a better understanding of the differences between vertical milling machines and horizontal milling machines.

Bavarder sur Internet

Maximize Efficiency: Horizontal Mill vs. Vertical Mill ...

Vertical mills also offer excellent rigidity due to their design. The vertical orientation of the spindle provides better support for heavy cutting loads compared to horizontal mills. This results in improved stability and accuracy during machining operations. Another benefit of vertical mills is their compact footprint.

Bavarder sur Internet

Vertical–Horizontal Coupling Vibration of Hot Rolling Mill

2021.1.18 This study establishes a vertical–horizontal coupling vibration model of hot rolling mill rolls under multi-piecewise nonlinear constraints considering the piecewise nonlinear spring force and piecewise nonlinear friction force constraints of the hydraulic cylinder in the vertical direction of the rolls, the piecewise stiffness constraints in the

Bavarder sur Internet

Difference Between Horizontal and Vertical Boring Machine

2023.3.9 A horizontal boring machine or horizontal boring mill is a type of industrial machinery used to enlarge or bore holes in large and heavy workpieces. It is commonly used in the manufacturing industry for drilling or boring machining precise and accurate holes in large components such as engine blocks, turbine casings, and gearboxes. The machine ...

Bavarder sur Internet

Difference between Horizontal Axis and Vertical Axis Wind

2022.9.22 Difference between Horizontal Axis and Vertical Axis Wind Turbines - A Wind Turbine is a device which uses kinetic energy of blowing wind to generate electrical energy. A wind turbine consists of two or three rotor blades which are mounted on a rotor. When the blowing wind exerts a lift and drag force on these blades, the rotor starts

Bavarder sur Internet

Horizontal vs. Vertical in Sawmills and Milling

2013.11.7 Horizontal vs Vertical log splitters Started by Wrace on General Board. 20 Replies 19481 Views Last post: October 09, 2004, 12:38:28 PM by Timberwerks : horizontal vs vertical bandmill Started by james on Sawmills and Milling. 17 Replies 5060 Views Last post: March 07, 2007, 01:38:56 PM by slowzuki

Bavarder sur Internet

Vertical vs horizontal mill Page 2 - Practical Machinist

2007.1.13 As a home workshop machine a plain horizontal mill gets 2 out of 10 from me,one with a vertical head 7 out of 10,one with a quill 10 out of 10,in other words a turret mill. Most turret mills have horizontal attachments available, With a quill you can drill/bore holes at an angle,or a compound angle if its a BP,it can,t be done without a quill.

Bavarder sur Internet

Horizontal vs. Vertical Milling: Which Is Best For Your

2016.8.17 Vertical Mills features spindles (cutting elements) that are aligned vertically. Horizontal Mills have a spindle that is parallel to the ground. Although the job of both machine types is the same, the production method of job completion looks a little differently. There are pros and cons to both machining choices, and it’s important to note ...

Bavarder sur Internet

Exploring Different Types of Wind Turbines Horizontal vs Vertical

2023.12.12 Horizontal axis turbines (HAWTs) are highly efficient and capable of converting wind energy into electricity at rates of 35-45%. HAWTs are proven technology with widespread deployment in wind farms worldwide. Vertical axis turbines (VAWTs) offer wind direction insensitivity, making them suitable for various environments.

Bavarder sur Internet

Horizontal Integration vs. Vertical Integration: Key Differences

2023.4.18 Key Takeaways. Horizontal integration is a business strategy where one company takes over another that operates at the same level in an industry. Vertical integration involves the acquisition of ...

Bavarder sur Internet

vertical - WordReference 英汉词典

有所遗漏?. 报告错误或提出改进建议. (relating to consecutive stages) 不同生产程序合并的. 纵向合并的. The company I work for uses a vertical hierarchy. (comprising specific industry) Simplified Chinese. The clothing company is an example of a vertical monopoly.

Bavarder sur Internet

Horizontal vs. Vertical Mill? - Practical Machinist

2009.1.22 3. Well, technically, the horiz mill is more versatile. It will run end mills and well as supported arbors. A vertical mill really cannot run a supported arbor, nor are they typically nearly as rigid. However, the lack of a quill makes the horizontal mill much more tedious for some of the more common uses of a mill, such as drilling and boring.

Bavarder sur Internet

(PDF) Performance Comparison of the Vertical and Horizontal

2023.2.23 Varied types/geometries of stirred mills have been produced by different manufacturers, and the comparison task has been accomplished for some of the technologies, i.e., Tower mill vs IsaMill.

Bavarder sur Internet

What is A Bed Type Milling Machine Difference Between Knee Mill

2023.2.22 1) Design: The key difference between a knee-type milling machine and a bed-type milling machine is in their design. A knee mill has a vertically adjustable knee, which is mounted on a column that is attached to the bed. The worktable is mounted on the knee and can be moved up and down along the Z-axis. In contrast, a bed mill has a fixed

Bavarder sur Internet

Articles liés

- machine avec fraisage et meulage

- djarum dans les mines de charbon

- concasseur à mâchoires à vendre indonésie

- scories usine de concasseur à ludhiana

- concasseur à cône avec la centrale de dépistage

- moulin de changfa Indonésie vendre

- rectifieuse pour charge minérale en afrique du sud

- Afrique concasseur de fumee pour les barspoudre de pierre

- machoire concasseur mobile concasseur vente

- charbon concasseur usha

- arbre à excentrique de la machine concasseur à machoires

- hercules Roadeo prix broyeur en Cameroun

- construction de ciment aide au broyage grâce

- liste complète des equipements de construction

- ciment de laitier processus de fabrication

- ancien broyeur de pierres pour calcaire

- miling etape de ciment

- concassage de pierre sud de la floride

- pieces de concasseurs a machoires de rechange

- diagrammes de flux des concasseurs giratoires

- surion concasseur prix de vente en inde

- vibrant processus de conception d'alimentation affinage de l'or et

- concasseur à cone occasion france

- broyeur de moulin de marteau de pc

- machines de concassage roi

- plant impact de concasseur de serie

- concassage de roche fabricants Algérie

- concasseur à cone prédire

- spec de ceinture utilise dans les mines

- bentonite traitement de rectification de sechage