Le broyeur à boulets ali baba vente

-

Afrique concasseur de charbon suède

-

componentes de una trituradora de piedra

-

mini raymond fabricant de moulin

-

molino triturador vendedor

-

broyeur société philippines

-

broyeur phosphate humide

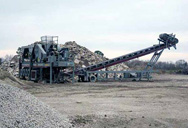

SKE: Crusher, Conveyor, Beneficiation Equipment

2023.10.9 SKE is a global manufacturer of crushers, mobile crushers, portable crushers, vibrating screen, belt conveyor, grinding mill, and mineral processing equipment in China. We provide solutions for aggregate

Bavarder sur Internet

Ore Processing Multotec

Ore processing is a chain of processing applications which treats run of mine to firstly high-grade concentrate (concentration of ores) and then to the pure mineral or metal. The

Bavarder sur Internet

Mining and Ore Handling Mining, Minerals

2023.8.22 Mining Ore Handling. Advanced automation and condition monitoring solutions to optimize mining mobile assets. Edge control and analytics to improve machine performance of stacker

Bavarder sur Internet

Conveyor Conveyor System Belt Conveyor DOVE

2024.1.21 DOVE Conveyor Belt Systems are highly efficient and rugged means of transporting the ore within the processing plant. DOVE Belt Conveyor Systems are designed for various complex working conditions

Bavarder sur Internet

Belt Conveyor Manufacturer Suppliers - SKE

5 天之前 SKE Industries provides belt conveyors for bulk material handling in power plants, cement plants, sand making plants, aggregate plants, ports, inland terminals, etc. K3 Belt Conveyor The K3 belt conveyor is a type of

Bavarder sur Internet

Mine Ore Belt Conveyor of Mineral Processing

2023.11.30 Mine Ore Belt Conveyor of Mineral Processing Plant. Working Principle. DT II fixed belt conveyor is a general series product. The transportation system combined with single or multiple machines used

Bavarder sur Internet

Iron Ore Conveyor Materials Handling Equipment - MHE

Our Iron Ore Conveyor Systems. We stand out from other iron ore conveyor manufacturers for several reasons. First, we custom manufacture every conveyor to meet the client’s

Bavarder sur Internet

Ore Beneficiation Plant Conveyor - SKE Industries

2024.1.5 Send Email Request A Quote What is the ore beneficiation plant conveyor? A beneficiation plant is a place to get ore concentrate. The belt conveyor is an essential equipment for ore dressing plant. It is

Bavarder sur Internet

Manganese Ore Process Plant - JXSC Mineral

This setup is for the manganese ore process: raw bin+vibration feeder>jaw crusher>belt conveyor>cone crusher>belt conveyor>vibration screen>belt conveyor>hopper+electromagnetic feeder>belt conveyor>ball mill>slurry

Bavarder sur Internet

Hard Rock Mining Equipment Crushing Plants

5 天之前 WIDE RANGE: DOVE is the leader and powerhouse in the mining equipment manufacturing industry and over the last 50 years has produced the largest range of Semi-stationary Hard Rock Plants

Bavarder sur Internet

Minerals Free Full-Text A Mine-to-Crusher

2022.8.18 Innovation has an important role in improving the productivity, safety and sustainability of mining operations. Historically, ore transport was done by diesel trucks, but with the commitment to reduce

Bavarder sur Internet

Ore Mining and Processing Logistics - BEUMER

2024.1.23 With our conveyor technology, the logistics of ores and ore minerals begin directly after mining. The rocks are transported to the warehouse via belt conveyors that are kilometers long. Our troughed belt

Bavarder sur Internet

Mining Conveyor Belt Manufacturers, Components

Conveyors are used to transport ores, concentrates and tailings across different stages of the mining cycle. Belt conveyors transport ore to feed processing plants and materials to stockpiles. Maintenance of conveyor systems is key to ensuring high efficiency, performance and productivity of mining operations.

Bavarder sur Internet

Company A-Z - Mining Technology

Modular Mineral Processing Plants. APS. Remote-Control Wireless Technology, and Dewatering and Recovery Systems ... Leading manufacturer of innovative conveyor technology and service provider, shortlisted in the SAFETY category in the 2021 Excellence Awards ... Closed Side Setting Measurement Device for Ore Crushers. MIP Process

Bavarder sur Internet

Processes Free Full-Text Research on and Design of an

2023.6.9 Conveyor belts are widely used in ore transportation in large-scale mines for their long transportation range, high safety, and strong economic applicability. Coal mine belt conveyors are not only traditional, simple mechanical conveying devices but also automatic control system operating devices that integrate safety, stability, and low power

Bavarder sur Internet

Christmas Creek Iron Ore Mine - Mining Technology

The conveyors currently span 10km, extended because of the effectiveness and reliability of this revolutionary infrastructure from the original 5km length. The processing plant at Cloudbreak crushes and screens high-grade ore to produce both lump and fine products. Infrastructure at Christmas Creek

Bavarder sur Internet

SKE: Crusher, Conveyor, Beneficiation Equipment Manufacturer

2023.10.9 S KE is not only a crushing, screening, feeding, conveying, ore dressing equipment manufactuer in China. We Can provide EPC and Turnkey Porject Services for global customers. We can help our customer set up aggregate plant (stone crushing and screening plant), construction waste recycling plant, mineral ore processing plant,

Bavarder sur Internet

CONCRETE BATCHING PLANTS - mekaglobal

2022.10.13 25 2 Units 195 RCC / Concrete Batching Plants / DAM Construction / Turkey 26 Special Design Precast Concrete Batching Plant Equipped With Double Mixer / Turkey 27 C 60 Precast Concrete Batching Plant Equipped With Planetary Mixer / Nicaragua 28 Precast Concrete Batching Plant Equipped With Planetary Mixer / Saudi Arabia

Bavarder sur Internet

Mining conveyors - TAKRAF GmbH

In 2019, TAKRAF delivered equipment for the principal ore transportation system for Chuquicamata, one of the world´s largest copper ore mines, moving ore extracted underground to an above-ground processing plant. This incredible system is one of the world's most powerful belt conveyor systems.

Bavarder sur Internet

Mine Ore Belt Conveyor of Mineral Processing

2023.11.30 Mine Ore Belt Conveyor of Mineral Processing Plant Working Principle DT II fixed belt conveyor is a general series product. The transportation system combined with single or multiple machines used

Bavarder sur Internet

System for Mine Belt Conveyors - MDPI

2023.6.9 conveyor for moving ore is a hot topic. 2. Industrial Plant Description A conveyor works as part of the panel conveying line. In the process of operation, the conveyor receives the materials conveyed by the previous belt conveyor (or scraper drift conveyor), conveys them along the panel, and transfers the materials to the next belt panel

Bavarder sur Internet

OPTIMIZATION OF IRON ORE PELLETS PRODUCTION IN

2022.7.22 Later it is sent to Raw mix hopper to mix the base mix and water perfectly. Then the iron ore pellets will sent through metallic conveyor into the furnace to undergo heating process at 1200 degrees. After the heating process, the heated base mix will converted into a semi liquid cake.

Bavarder sur Internet

Conveyor technology at one of the largest copper mines in

2020.5.27 Codelco is the world’s largest producer of copper and second largest producer of molybdenum. Over 100 years of opencast mining have resulted in a mine that is some 1000 m deep, 5000 m long and 3000 m wide. Once the rock had been mined by drilling and blasting, the ore and waste material were transported to the surface by trucks

Bavarder sur Internet

Minerals Free Full-Text A New Belt Ore Image

2020.12.11 In the field of mineral processing, an accurate image segmentation method is crucial for measuring the size distribution of run-of-mine ore on the conveyor belts in real time0The image-based measurement is considered to be real time, on-line, inexpensive, and non-intrusive. In this paper, a new belt ore image segmentation method

Bavarder sur Internet

China Mining Machine Manufacturer, Mineral Processing

1. a top manufacturer in complete set mineral processing plants including production and laboratory mining equipments. 2. with more than 15 years of experience in production sale and exported to over 50 countries. 3.with strictly QC during production and before delivery. 4. with a professional engineering team and installation team of 18 ...

Bavarder sur Internet

Small Scale Gold Mining Equipment - JXSC Mineral

Main Equipment: Ball mill, gold centrifugal concentrator, shaking table Flowchart explanation for 2tph rock gold processing plant This is a 2 TPH rock gold processing plant site from an Egyptian customer, it’s configured with a ball mill, gold centrifugal concentrator, and shaking table. Ore in transit bin is sent to ball mill via vibrating feeder and belt conveyor, then

Bavarder sur Internet

Current Status of Copper-Ore Processing: A Review

2021.9.8 ore processing plant, copper concentrate DOI: 10.3103 ... equipment manufacturing, and infrastructure. In 2019, global copper consumption was 29.44 million t, which is a 0.5% increase when compared to 2018. According to London Metal Exchanges, the average ... crushed ore is transported mainly by a belt conveyor system and, more

Bavarder sur Internet

Pilot Study on a New Conveyor Bed Magnetization Roasting Process

2023.3.28 Realizing the large-scale development and utilization of siderite, a difficult iron ore reserve, has great practical significance in ensuring the supply of iron ore resources. Therefore, a new in-house conveyor bed magnetization roasting–dry cooling process was pilot-tested using low-grade siderite from the Daxigou iron ore mine. A two-stage weak

Bavarder sur Internet

Mining Conveyors Make Transitions E MJ

2024.1.19 That overland conveyor delivers ore to the mineral processing plant 5 km away. The landscape surrounding the processing plant has been shaped by more than 100 years of mining at Chuquicamata. In addition to the various processing systems, waste heaps, railroad tracks, roads, pipelines and buildings scar the landscape.

Bavarder sur Internet

Mineral Processing Equipment Multotec China

With a branch in Tianjin, China, Multotec provides leading mineral processing technology for gold, coal and rare earths beneficiation plants: Full range of hydrocyclones, samplers, slurry pumps, wear parts, valves, wedge wire screens and spirals. Multotec in China is committed to world-leading quality assurance and environmental practices.

Bavarder sur Internet

Crushing Plant Design and Layout Considerations - 911

2016.2.24 The process design criteria define the project’s production requirements, and typically include those shown in Table 1. Table 1 Production requirements Process Description General Ore Characteristics Operating Schedule General Primary crushing Fines crushing Storage reclaim Maximum rock size in the feed Ore types, compressive

Bavarder sur Internet

Current Status of Copper-Ore Processing: A Review

2021.9.8 Abstract An analysis of flowsheets for processing sulfide and oxide copper ores, reagent modes, processing equipment, and flotation indicators in some domestic and foreign processing plants and productions is carried out. Autogenous and semiautogenous mills are commonly used in the primary grinding stage in ore processing plants, which

Bavarder sur Internet

2023/sbm zinc ore mill high quality in zinc mining process

sbm zinc ore mill high quality in zinc mining processHome Gold Grind Machine The wet pan mill is named by the diameter of roller.Φ1300,Φ 1350,Φ 1400,Φ 1500,Φ 1600 is suitable for selection of iron ore,molybdenum ore,lead ore,zinc ore,antimony ore and so on.Φ 850,Φ 900,Φ 1000,Φ 1100,Φ 1200 is suitable for selection of gold ore.As their small

Bavarder sur Internet

Gold Processing Plant Multotec

After the gold ore has been removed from the earth using mining equipment, it is sent to a gold processing plant. The typical gold processing plant begins with a cone crusher, to reduce the particle size of the ore. Next, it is loaded on a conveyor belt, where an overbelt magnet removes tramp metal from the gold mining process. The ore goes for ...

Bavarder sur Internet

BELT CONVEYOR - 911 Metallurgist

2021.5.8 Belt Conveyors. The belt conveyors used to transport the ore in the crushing plant commonly run at 100 to 200 ft. per min. and vary in width from 16 to 36 in. according to the tonnage to be handled. Their capacities and power requirements are given in Table 4.

Bavarder sur Internet

Belt Conveyors TAKRAF - TAKRAF GmbH

The main conveyors at this project are the tunnel conveyor PC 2 and the overland conveyor PC 3. Tunnel conveyor PC 2. With 16,820 m pulley center distance and 471 m lift this conveyor is still one of the largest conveyors worldwide. With the task to design an energy efficient system with reduced capital costs for belting and drives several ...

Bavarder sur Internet

Bulk Material Handling Equipment Systems - FEECO

2023.6.16 FEECO’s engineered bulk material handling equipment and systems are rugged, dependable, and built to last. We can design and supply flexible bulk material handling systems for industries ranging from minerals and ores, to fertilizers and chemicals. Our custom equipment and systems can assist in every aspect of handling, including

Bavarder sur Internet

Chrome Processing Plant, Equipment - JXSC Machinery

5 天之前 1. Feeding: Excavator or truck send raw ore into the raw material hopper, through vibrating feeder evenly feeds trommel screen.The vibrating feeder with grizzly bar, gap 75mm, and over 75mm rock will be sent to the waste stockpile via belt conveyor. 2. Washing stage: 0-75mm material is sent to trommel screen for sieving out 0-2mm and 2-75mm.

Bavarder sur Internet

Mining Conveyor System for Underground Open-pit Mine

2024.1.24 In most mining plant, we just need in-plant conveyors. And the conveyor system may be very complicated. It often consists of many belt conveyors. We just list some of them below: 1. tripper conveyor car: used to stockpiling raw ores; 2. Universal belt conveyor: used to convey raw ores and concentrate ores; 3. Corrugated sidewall belt

Bavarder sur Internet

Articles liés

- discours du design du concasseur

- il concasseur Indonésie machoires

- optimisation de concasseur à mâchoires

- concasseur de pierre bruit

- fils calcaire de concassage

- concasseurs à mâchoires de la capacité

- conception du broyeur scrow en plastique

- malaisien fait concasseur à mâchoires vidéo

- meulage support de broche

- rapport de projet sur le broyeur de charbon

- meunerie du moulin ultrafine

- machine de fabrication d alliment de btaille

- Fabricants De Tubes A Boulets

- minerai de fer concasseurs

- coquille d'hutre équipements de concassage

- centrale mobile de lavage total

- conception concasseur trémie

- concasseur à cone triaxial

- concassage concasseur et demande

- broyeur a Mica fabricants de broyage

- concasseur mobile pour le recyclage Autriche

- location liste de prix pour les plantes de lumieres des fetes

- broyeur machines en italie

- technique de l usine de Calcite a vendre

- broyeurs à boulets Irlande

- processus dl'extraction de la pierre en chaux ppt

- machines de broyage d'agrégats de EtatsUnis

- construction de l usine de traitement des matriaux en mtal de slovaquie

- Pvc Pneumatique Bricolage Peut Concasseur

- Séparateur vibrant de tamisage