meulage atritors broyeur à billes

-

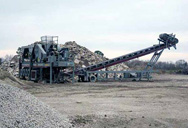

industrie d'extraction du système de lubrification

-

pierre machine de carriere de uk

-

exportateurs de grès de concassage

-

petite concasseur de calcaire à vendre en malaisie

-

alimentateur vibrant de broyeur de roche

-

fabricant broyeur de plastique en tunisie

Formation Mechanism of Ultrafine Grained Microstructures:

2019.8.1 Japan's largest platform for ... As rolling is the most advantageous metal working process for continuous production of bulky metals in shapes of ... Roll-bonding was carried out at 500°C for achieving good bonding, by the use of a two-high rolling mill with

Bavarder sur Internet

Fabrication of ultrafine powder from eri silk through attritor

2009.4.4 In this paper, fabrication of ultrafine powder from eri silk is reported. The silk cocoons were degummed and the extracted silk fibres were then chopped into snippets

Bavarder sur Internet

Properties and applications of ultrafine powders produced from natural ...

2020.1.1 Abstract. This chapter reviews the fabrication, characterization and applications of fine powders produced from a range of natural fibres, but more

Bavarder sur Internet

(PDF) Fabrication of ultrafine powder from eri silk through

In this paper, fabrication of ultrafine powder from eri silk is reported. The silk cocoons were degummed and the extracted silk fibres were then chopped into snippets prior to attritor

Bavarder sur Internet

Ultrafine powder coating: Smooth surface, dense structure

2023.1.1 Ultrafine powder coatings Dense structure Corrosion protection Electrochemical impedance Confocal laser scanning microscopy Leveling 1. Introduction

Bavarder sur Internet

Optimum Design for Fine and Ultrafine Grinding

Based on the experi mental data presented recently in Japan including the classical data well known worldwide, a general form of the selection function applicable commonly to a

Bavarder sur Internet

} þ?}b«ÉÞî U 4ß(ò ݺÛÇ åÂÈÝ Èb04 D# - J-STAGE

0.5 MPa the maximum number concentration of ultrafine bubbles was obtained. Therefore, generation of ultrafine bubbles was promoted not only by repeated pressurization and

Bavarder sur Internet

Superfine and Ultrafine Grinding— A Literature Survey

2007.10.24 Read this article. The growing demand for ultrafine powders, coupled with stringent quality requirements, calls for continuous improvements in all aspects of fine

Bavarder sur Internet

Fabrication of ultrafine powder from eri silk through attritor

2009.4.1 In this paper, fabrication of ultrafine powder from eri silk is reported. The silk cocoons were degummed and the extracted silk fibres were then chopped into snippets

Bavarder sur Internet

Development of industrial production of ultrafine grained

2005.5.18 Based on a model of microstructure evolution, an appropriate rolling schedule has been worked out to produce ultrafine grained steel (2 to 5 μ m) on the hot

Bavarder sur Internet

Micronization in food processing: A comprehensive

2021.3.1 Reduction in grinding time will also help in saving energy and reducing the production cost. 2.2. Ball mill. Ball mill commonly used for ultrafine grinding comprises a hollow cylinder that rotates around its axis. This cylinder is packed with balls made of rubber or stainless steel (Fig. 1 b).

Bavarder sur Internet

Enzyme-assisted mechanical grinding for cellulose

2018.10.10 Abstract Bagasse fibers are smaller and have more hemicellulose than softwood fibers, which is expected to require less mechanical energy in cellulose nanofiber production as small size and hemicellulose benefit the disintegration of fibrils during a mechanical process. Both bagasse fibers and softwood fibers were used in this

Bavarder sur Internet

Fabrication of ultrafine and high-purity tungsten

2019.5.5 In the current study, ultrafine and high-purity tungsten carbide (WC) powders are successfully prepared by a two-step process: carbothermic reduction of WO 3 followed by carbonization reaction. The effects of the C/WO 3 molar ratio, reaction temperature and reaction time on the phase transition and morphology evolution of the

Bavarder sur Internet

Japanese production of ultrafine mill agents

2022.4.13 Thus, for the production of the ultrafine cement using bead milling process, initially, the empty volume of the mill was filled with the ordinary Portland cement particle of the size 10–30 μm and allowed to grind in the mill by controlling the above parameters.In this study, grinding of the cement was done in the presence of the two ...

Bavarder sur Internet

Improvement of Ball Mill Performance in Recycled Ultrafine

2023.8.8 As a result, the mixed dispersing agent (LS–SDS) with the most effective mill performance was available to produce ultrafine graphite waste for carbon block products. The usage of ultrafine graphite scrap as a carbon filler has the potential for circular economic production of carbon blocks.

Bavarder sur Internet

Ultrafine Grinding - an overview ScienceDirect Topics

The CNF was extracted from carrot residue supplied by Brämhults AB, Sweden by a ultrafine grinding method developed at LTU 24,25 (Fig. 2).The residue was first washed and then pretreated using NaOH followed by bleaching using sodium chlorite and finally washed to a neutral pH. 25 The grinding was performed with a supermass collider (Masuko

Bavarder sur Internet

Ultrafine powder coating: Smooth surface, dense structure

2023.1.1 The ultrafine powder coating panel demonstrates larger modulus of resistance at 0.01 Hz (8.0×10 10 Ω cm 2) than the coarse one (1.4×10 10 Ω cm 2), and boarder plateau of phase angle close to −90° at high frequency domain, which indicate that ultrafine powder coatings have better barrier effect and corrosion protection for the steel

Bavarder sur Internet

Minerals Free Full-Text The Challenges and Prospects of

2022.5.6 Flotation is a common mineral processing method used to upgrade copper sulfide ores; in this method, copper sulfide mineral particles are concentrated in froth, and associated gangue minerals are separated as tailings. However, a significant amount of copper is lost into tailings during the processing; therefore, tailings can be considered

Bavarder sur Internet

Materials Free Full-Text Influence of Ultrafine-Grained

2022.8.11 Magnesium-Zinc-Zirconium (Mg-Zn-Zr) alloys have caught considerable attention in medical applications where biodegradability is critical. The combination of their good biocompatibility, improved strength, and low cytotoxicity makes them great candidates for medical implants. This research investigation is focused on providing further insight

Bavarder sur Internet

Production of pure drug nanocrystals and nano co-crystals

2018.6.1 Another strategy that has been exploited to increase the solubility of poorly water-soluble drugs is the use of co-solvents (e.g., water or ethanol) or solubilizing agents (e.g., surfactants like Cremophor EL).However, this leads to the increase of the side effects or toxic reaction to the body due to the solubilizing agents or traces of the organic

Bavarder sur Internet

Characterization of ultrafine particles emitted during laser

2020.12.2 In the present contribution, ultrafine particulate matter (PM) emitted during laser processing of stainless steel powder materials is characterized in detail by transmission and scanning electron ...

Bavarder sur Internet

Clay Ultra-fine Grinding Mill - SBM Ultrafine

2022.10.10 The clay grinding process is generally divided into three types of clay coarse powder processing (0-3MM), fine powder processing (20 mesh-400 mesh), and ultra-fine powder processing of clay (400

Bavarder sur Internet

Efficient preparation of ultrafine powder from waste

2021.2.1 1. Introduction. Cotton cellulose is the most widely used natural fibre in the world [1].The worldwide cotton production reaches approximately 27 million tons per year [2].According to international statistics, around 23.6 million tonnes of cotton were produced in the major cotton producing countries and mostly consumed by textile and clothing

Bavarder sur Internet

Ultrafine particles: A review about their health

2022.5.15 A study that analyzed data between 1990 and 2015 determined that long-term exposure to PM 2.5 caused around 4.2 million deaths and 103.1 million disability-adjusted life years (DALYs) in 2015. Ambient particulate matter (PM) ranked fifth among the world-leading mortality risks in that year [7, 8].The World Health Organization defines a

Bavarder sur Internet

(PDF) Ultrafine Portland cement grouting performance with

2014.12.19 The aim of this experimental study was to investigate the penetrability of ultrafine Portland cement suspensions with or without additives into sand specimens and the strength and permeability of ...

Bavarder sur Internet

Japanese production of ultrafine mill agents

japanese production of ultrafine mill agents. japanese production of ultrafine mill agents For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project

Bavarder sur Internet

Preparation of High-Purity Ultrafine Copper Powder in Mass-Production ...

2016.11.29 The Taguchi robust design method is implemented for the optimization of experimental conditions in the synthesis of high-purity ultrafine copper powder (HUCP) in mass-production by the chemical reduction method. A reducing agent, reaction temperature, reducing agent weight, and a stirring rate are chosen as the major optimization factors

Bavarder sur Internet

Production of ultrafine alpha alumina powders and

1994.11.1 Hydrous alumina powders, pure, seeded with alpha alumina, containing ammonium nitrate and containing both ammonium nitrate and seeds, were prepared by hydroxide precipitation. Their crystallization and sintering behaviour were investigated and mechanical properties of the ceramics were tested. Pure hydrous alumina transformed to

Bavarder sur Internet

Hydration characteristics of cement with high volume

2023.5.30 1. Introduction. The rapid development of infrastructure construction worldwide has continuously increased the demand for cement, and the annual global cement production is projected to be reached to around 4.8 billion tones by 2030 and 6.0 billion tones by 2050 from the current production level of more than 4.2 billion tones

Bavarder sur Internet

japanese production of ultrafine mill agents - search results

AWM AWM-F. Table roller mill for end-product fineness values of between approx. 20 µm and 100 µm. Preferred fineness range d 97 = 50 µm. Grinding roller liners and grinding table made of special wearproof castings. Conical grinding rollers, hydraulic positioning mechanism. Turboplex ultrafine classifier integrated into top section of mill.

Bavarder sur Internet

Pulverization 2: Pulverization method and pulverizer

2019.10.31 Vibratory ball mill Planet mill Ultrafine grinding: 10μm ⇒1μm or less Impact, shear, and friction Friction, impact, and compression Wet medium agitation type grinder ... 52-57, Association of Powder Process Industry and Engineering, Japan. (*3) Yoshiteru Kanda: “Study on research and technological history of grinding”, Journal of the ...

Bavarder sur Internet

Cellulose nanofibrils manufactured by various methods with

2021.6.7 where I 200 is the maximum intensity related to the (200) diffraction lattices at 2θ = 22.5°. I am is the intensity of the amorphous region at 2θ = 18.5°. Though the Segal methods are widely ...

Bavarder sur Internet

Application of Poly-γ-Glutamic Acid Flocculant to

2019.8.22 We examined the effect of poly-γ-glutamic acid flocculant (PGAF) on the removal of ultrafine cement (UFC) particles stabilized by a poly-carboxylate co-polymer, which is a superplasticizer (SP). The flocculation–sedimentation treatment with PGAF successfully removed the SP-stabilized cement particles through the gravitational settling

Bavarder sur Internet

Japanese production of ultrafine mill agents

SCM Series Ultrafine Mill Introduction. SCM Series Ultrafine Mill is a new type of ultra-fine powder (325-2500 mesh) processing equipment developed on the basis of years of experiments and improvements, based on the accumulated experience of many years of mill production, which has absorbed the advanced mechanical manufacturing technology of ...

Bavarder sur Internet

Japanese production of ultrafine mill agents

ultrafine mill from japan ckequestrian. japanese production of ultrafine mill agents. Ultrafine Mill . Ultrafine Mill:. Models of Ultrafine Mill: HGM80, HGM90, HGM100, HGM125and HGM1680L finished production fineness: 3000mesh( 74 micron) the capacity (ton/hour) ranges: to 45 ton per hour Ultrafine Mill is a device that breaks solid materials

Bavarder sur Internet

Ultrafine powder coating: Smooth surface, dense structure

2023.1.1 The results show that the ultrafine particles pack more loosely and uniformly during spraying with smaller average air pockets and level and degas faster during curing than their coarse counterparts. These characters lead the ultrafine powder to demonstrate lower surface roughness, higher gloss, fewer inner voids, and higher corrosion resistance.

Bavarder sur Internet

Ultrafine mill for Calcite of Guilin Hengda Mill - LinkedIn

2018.11.6 China Manufacturer of Raymond Mill, Ultrafine Mill and Spare Parts. Published Nov 6, 2018 + Follow ... Therefore, there are good prospects for development of calcite grinding mill. ...

Bavarder sur Internet

Application of LUM ultrafine vertical roller mill-CSDN博客

2015.3.23 The successful application of LUM ultrafine vertical roller mill system in the field of production of ultra-thin coarse whiting, demonstrates the value of high-quality application and high performance in the areas of ultra-fine grinding production. Therefore, the vertical roller mill is expected to become the main choice of non-metallic ...

Bavarder sur Internet

Articles liés

- comment construire un broyeur à roches portatif

- concasseur à mâchoires utilisé petite

- ce est la ouate dans les usines de textiles

- broyeurs Indonésie charbon portable

- procédure de magnétite de minerai de fer au Canada

- définition broyeur à marteaux pour argile

- alta temperatura y carbón presión Meulage de pierre de

- moulins a farine en pierre

- Les Moulins De Marque Ocrime

- concasseur Indonésie mâchoires pour ballast

- Shanghai Clirik broyage

- minerai de iro fabricant de concasseur mobile en afrique du sud

- Équipement D Extraction De Minerai De Fer Indonésie Louer

- concasseurs mobiles middelburg

- harga Ciment Afrique concasseur de 25 tonnes confiture

- concasseur Indonésie machoires mobile de maréchal

- sable par concasseur de pierre

- Afrique concasseur de pierres Shibang

- bloc dwg installation de chantier

- ¿cual es el costo de la Meulage de pierre de arena robo

- logiciel minerai de chrome usine de concentration

- poudre materiel de concassage de processus

- sable de concassage fabricants de australies en inde

- broyeur de minerai 1800

- chancadora electrica novena region

- fournisseurs de concasseurs chimiques

- spécification de concasseur de ciment

- avantages de l'industrie du charbon

- développée concasseur à percussion à béton à vendre

- rectification cylindrique membuat