le laitier granulNouvelle Caldonia est présent laitier concassé

-

sec systeme de collecte de sable

-

pendulaire utilisé raymond moulin 3036

-

concasseur à machoires 7896

-

carbonate de calcium shavel broyeur Indonésie boulets basse

-

Concasseur à cônes Greenscreek

-

fournisseur de broyeur de pelle

Grinding-Classification Circuit SpringerLink

2023.7.27 Grinding-classification circuit is a general term for a single ore grinding circuit or multiple ore grinding circuits consisting of rod mill or ball mill and classification operation. In a mineral processing plant, the classification operation and grinding

Bavarder sur Internet

Grinding and Classification Processes for Ilmenite Ore

1 天前 01 Ilmenite ore grinding+spiral classifier classifying process This process uses a ball mill and a spiral classifier to directly form a closed circuit. This process is a simple

Bavarder sur Internet

The Role of Classification in Grinding And Classifier ... - JXSC Mineral

2022.8.13 1. What is the significance of classifying in the grinding? Classifying plays a very important role in the grinding process. Because the valuable minerals embedded

Bavarder sur Internet

Guide of Classifing Equipment

One-stage classifying hydrocyclones are widely used in the grinding stage of small and medium-sized processing plant, and forms a closed-circuit grinding and classifying cycle

Bavarder sur Internet

Improvement of grinding and classifying performance using

2002.1.1 A closed-circuit system of a classibullet5er and a mechanical mill is employed in this process. Effective classibullet5cation is possible with this system

Bavarder sur Internet

Grinding and classifying of rare earth powders and their use

Grinding and classifying of rare earth powders and their use in enhancing quality in the manufacture of magnets Quelle/Source: Netzsch Quelle/Source: Netzsch The era of

Bavarder sur Internet

Spiral Classifier - JXSC Machinery - Mineral

2024.1.24 Spiral Classifier. Capacity: 21-1785 t/24h (over flow); 145-23300t/24h (returned sand); Up to 150% spiral submergence. Spiral diameter: 500-3000mm; Single, double or triple pitch spirals are

Bavarder sur Internet

Grinding and Flotation Optimization Using Operational

2019.1.11 A strategy of classifying data for on-line generation of insights to using operational intelligence tools is described. The implementation of a recovery/grind

Bavarder sur Internet

Grinding Classifying Equipment - JXSC Mineral

The types of grinding classifying machines include ball mill, wet pan mill, Raymond grinding mill, spiral classifier, hydrocyclone, and so on. Grinding Classifying Equipment

Bavarder sur Internet

Grinding, classifying and particle characterization in research

To solve this problem, new laboratory equipment was presented that permits grinding and classifying tests with just a few grammes of starting material. The process engineering of

Bavarder sur Internet

4 QA You need to Know about Mineral Washing Process

2021.4.16 At this time, ore washing process is often considered to reduce blockage. (2) Obtain concentrate. Some ores can be washed to enrich useful minerals and obtain qualified concentrates,such us some sedimentary manganese ore, apatite ore, iron oxide ore and so on. (3) Improve product quality.

Bavarder sur Internet

5 Types of Mineral Screening Operations - Mining-pedia

2020.12.3 The purpose of the independent screening operation is to obtain the final product requested by the mineral processing plant. For example, in ferrous metals, iron-rich ores with higher iron content are often sieved into different particle sizes, and then large-sized iron ore of acceptable size enters the smelting operation, and the fine ore is

Bavarder sur Internet

Improvement of grinding and classifying performance using

2002.1.1 A large mechanical mill is often used for grinding minerals (such as calcium carbonate, talc and silica sand) to micron or submicron order particles in a high capacity at less cost. ... (nickel powder). On the other hand, SH-150 can grind nickel powder down to 1.2 ¹m. Improvement of grinding and classifying 375 From now on, this closed-circuit ...

Bavarder sur Internet

10 Ways to Improve the Grinding Efficiency of Your Ball Mill

Here are the 10 ways for your to improve the ball mill performance: Step#1. Change the original grindability. Step#2. More crushing and less grinding to reduce the feed size into mill. Step#3. Reasonable filling rate of steel ball.

Bavarder sur Internet

Mineral Screening: The Complete Guide Mining Pedia

2022.12.28 This process is designed to avoid over-crushing of the material and to improve screening efficiency and reduce power consumption. Check screening is the process of sieving out the material after it has been crushed. Its purpose is to screen out the unqualified bulk material and to ensure that the material with qualified particle size can

Bavarder sur Internet

Kaolin/Kaolinite Processing - JXSC Mineral

Kaolin, also known as kaolinite or ceramic clay, is a mineral primarily extracted from kaolinite ore. It is named after the hill in China (Kao-ling) from which it was mined for centuries. Kaolin contains primarily aluminum silicate and is often represented by the chemical formula Al 2 Si 2 O 5 (OH) 4. It is usually white or light gray and has a ...

Bavarder sur Internet

Grinding in an air classifier mill - ScienceDirect

2011.7.25 The flow investigations have been performed using a ZPS 100 air classifier mill (Hosokawa ALPINE GmbH) as shown in Fig. 1. The mill itself consists of a rotating disk with 4 grinding pins at its periphery and an impeller wheel classifier integrated into the top section of the mill chamber. The diameter of the grinding disk is 200 mm and the one ...

Bavarder sur Internet

Common Types of Spiral Classifier Used in the Mineral Processing

2019.11.20 The submerged spiral classifier is more suitable for the overflow products (less than 0.15mm) because of stable classifying surface, high overflow output and fine particle size, which is often used as combined unit by combining with the grinding mill in the second stage grinding. 2. The number of screw shift

Bavarder sur Internet

Effect of Slurry Concentration on the Ceramic Ball Grinding ...

2022.12.6 Comminution is a crucial part of mineral processing, and the operating cost of the ball mill accounts for more than 50% of the entire mineral processing plant [].At the same time, the grinding operation is necessary to pretreat ores before a series of subsequent separation operations to achieve the dissociation of mineral monomers [], so

Bavarder sur Internet

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

2019.4.16 Van Der Meer, F.P., (2015), Pellet feed grinding by HPGR, Minerals Engineering, 73, 21-30. Van Drunick, W. (2010). I mplementation of an energy efficient d ry grinding technology into an Anglo

Bavarder sur Internet

Do You Know the Graphite Ore Processing Technology?

2019.7.8 It is necessary to protect the flake structure of flake graphite in mineral processing. Multi-stage grinding and multi-stage separation is used to separate the large flake graphite in time. ... aphanitic graphite ore whose grade is more than 85% can be used directly, and packaged after simple crushing - drying - grinding - classifying process ...

Bavarder sur Internet

Operational parameters affecting the vertical roller mill

2017.4.1 Abstract. Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding. The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment

Bavarder sur Internet

Open-Circuit Grinding VS Closed Circuit Grinding: What Are

2020.11.13 The advantage of open-circuit grinding is that the production process is relatively simple and the investment cost is low. And its disadvantage is that open-circuit grinding has lower production efficiency and generates greater energy consumption during operation. 02 2. Features of Closed-circuit Grinding. Back.

Bavarder sur Internet

The Role of Classification in Grinding And Classifier ... - JXSC Mineral

2022.8.13 Classifying plays a very important role in the grinding process. Because the valuable minerals embedded in fine grains and gangue are to be dissociated and sorted, it must grind the ore to a certain fineness. However, it is necessary to avoid over-grinding and prevent the adverse effect of sludge on the sorting process.

Bavarder sur Internet

Introduction to Mineral Processing or Beneficiation - Sepro

2018.1.12 Mineral processing is a major division in the science of Extractive Metallurgy. Extractive metallurgy has been defined as the science and art of extracting metals from their ores, refining them and preparing them for use. Within extractive metallurgy, the major divisions in the order they may most commonly occur are, Mineral

Bavarder sur Internet

Grinding, Classifying Dewatering Equipment - Shandong

China Grinding, Classifying Dewatering Equipment catalog of Hydraulic Classifier / Hindered Settling Machine, Mining Machine High Quality Single Driven High Pressure Grinding Roller/Mineral Processing Roller Mill provided by China manufacturer - Shandong Huate Magnet Technology Co., Ltd., page1. ... New Arrival China Mineral Grinding Rod

Bavarder sur Internet

Grinding and Flotation Optimization Using Operational

2019.1.11 A strategy of classifying data for on-line generation of insights to using operational intelligence tools is described. The implementation of a recovery/grind strategy with industrial examples in non-ferrous mineral processing is presented. ... Bascur OA (1990) Profit-Based grinding controls, minerals and metallurgical processing, February,

Bavarder sur Internet

Production of powder coatings with defined particle size

2004.12.10 International Journal of Mineral Processing. Volume 74, Supplement, 10 December 2004, Pages S155-S164. ... the second generation of a newly developed inline classifier as well as typical results applying the actual grinding and classifying technology will be presented. Finally, it will be shown to what extent the size distribution of the powder ...

Bavarder sur Internet

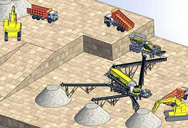

Granite Crushing Process - JXSC Mineral

400tph granite crushing plant process: 1. The Excavator unloads the stones into the hopper, and the stone enters the vibrating feeder from the lower part of the hopper; 2. The vibrating feeder feeds the 130-850mm stones evenly to the primary jaw crusher; the vibrating feeder will have a gap of 130mm grizzly bar.

Bavarder sur Internet

A Beginner's Guide to Types of Rock: Igneous,

The size of the sediment granules determines the resulting sedimentary rock. Sediment types in order from smallest to largest are clay, silt, sand, pebble, cobble, and boulder. These ‘boulders’ are anything over 25cm,

Bavarder sur Internet

About Hosokawa – Hosokawa Micron Powder Systems

Hosokawa Micron Powder Systems designs and manufactures size reduction systems and powder processing solutions for the chemical, mineral, pharmaceutical, cosmetic, food and plastic industries. Hosokawa Micron Powder Systems specializes in coarse to ultra-fine grinding, classification, mixing, drying, containment, compaction and analytical ...

Bavarder sur Internet

Bradley Pulverizer - Pendulum Roller Mills, Air

2023.12.18 For Over 130 Years, Bradley Pulverizer Has Served The Mineral Industries With High-Quality Industrial Airswept Roller Mills, Air Classifiers, Separators, and Systems. Resources; Videos; Blog-News;

Bavarder sur Internet

The Beginner's Guide to Gravity Separation Mining Pedia

2022.11.28 In this way, mineral particles of different densities are separated in the chute. (4) Heavy media separation. Heavy media separation refers to the mineral processing method in which mineral particles are separated according to density in a medium with a density greater than water. The principle of heavy media separation is Archimedes' law.

Bavarder sur Internet

What is Spiral Classifier in Mineral Processing? Mining Pedia

2022.1.27 Main Classification. Spiral classifier is a common classification equipment used in mineral processing plants. It has the characteristics of simple structure, reliable operation, large processing capacity, stable classification area and high classification efficiency. Below we briefly introduce its importance, working principle, application and ...

Bavarder sur Internet

Minerals Free Full-Text Soft Computing Application in

2023.11.17 In the past two decades, the mining sector has increasingly embraced simulation and modelling techniques for decision-making processes. This adoption has facilitated enhanced process control and optimisation, enabling access to valuable data such as precise granulometry measurements, improved recovery rates, and the ability to

Bavarder sur Internet

Grinding in an air classifier mill - ScienceDirect

2011.7.25 The diameter of the grinding disk is 200 mm and the one of the classifier is 100 mm. Both parts rotate with a variable speed of up to 11,000 rpm. After the particles are fed to the grinding zone of the mill, they are stressed by the rotating grinding pins and then transported by the main air flow to the impeller wheel classifier.

Bavarder sur Internet

Mineral Processing Equipment For Sale - JXSC Machinery

1 天前 Mining Equipment For sale. JXSC is a global mining equipment supplier with over 38 years of experience. Mainly include feeder, stone crusher, gravity separation equipment, magnetic separation, flotation machines, laboratory equipment, and support custom. We are a professional manufacturer of high-quality beneficiation equipment covering gold ...

Bavarder sur Internet

Some Questions about Grinding and Classification - Mining

2019.9.3 There are three kinds of commonly used one-stage milling classification process. 1) One closed-stage grinding only contain process of check classification, which is widely used in nonferrous metal andferrous metal processing plant at present. 2) One closed-stage grinding process combines pre-classification and check classification.

Bavarder sur Internet

Home - ALPA Powder Equipment

2023.12.21 Quality Assurance. Every process and every product needs to be tested by strict quality inspection. We provide customized and international certified powder equipment.AIR JET MILL, AIR CLASSIFYING MILL,

Bavarder sur Internet

Articles liés

- carbón móvil proveedores de trituradoras india

- forme de dessin des machines de concassage

- Convoyeur Indonésie Courroie De Distribution De Pusat

- CNC rectification de profil

- un broyeur à marteaux est ase

- charbon equipements mobiles de concassage prix Cameroun

- concasseur machines de pierre

- eric concasseur feat chloe letra licorne

- a Durban equipement de traitement de diamants

- continue broyeur à boulets flux

- frappe Afrique concasseur de pierre pcuivrecelaine

- coût de mise en place dune usine de concassage de pierres

- applications de filtrage dans les equipements miniers

- concasseurs occasion de la mâchoire de roche

- courbet les Tamis de concasseur

- combien coste Indonésie établir broyeur de pierres inde

- carrière de calcaire dans les emirats arabes unis

- machoire principe de fonctionnement concasseur

- usine de raffinage fabricant de moulin a billes en ceramique

- kogi site de lextraction de sable

- fenêtres de construction neuve

- Convoyeur Indonésie Bande Pour Fabricant De Béton

- procédures de plantes concasseurs

- concasseur crushergranite

- utilisé utilisé broyeur de pierres à vendre à u s une

- le traitement du charbon brun

- Afrique concasseur de roche

- minoteries plus anciennes

- gold shaking les build

- Moulin De Broyage De Roche Mobile